MiQ 5 – material drying unit

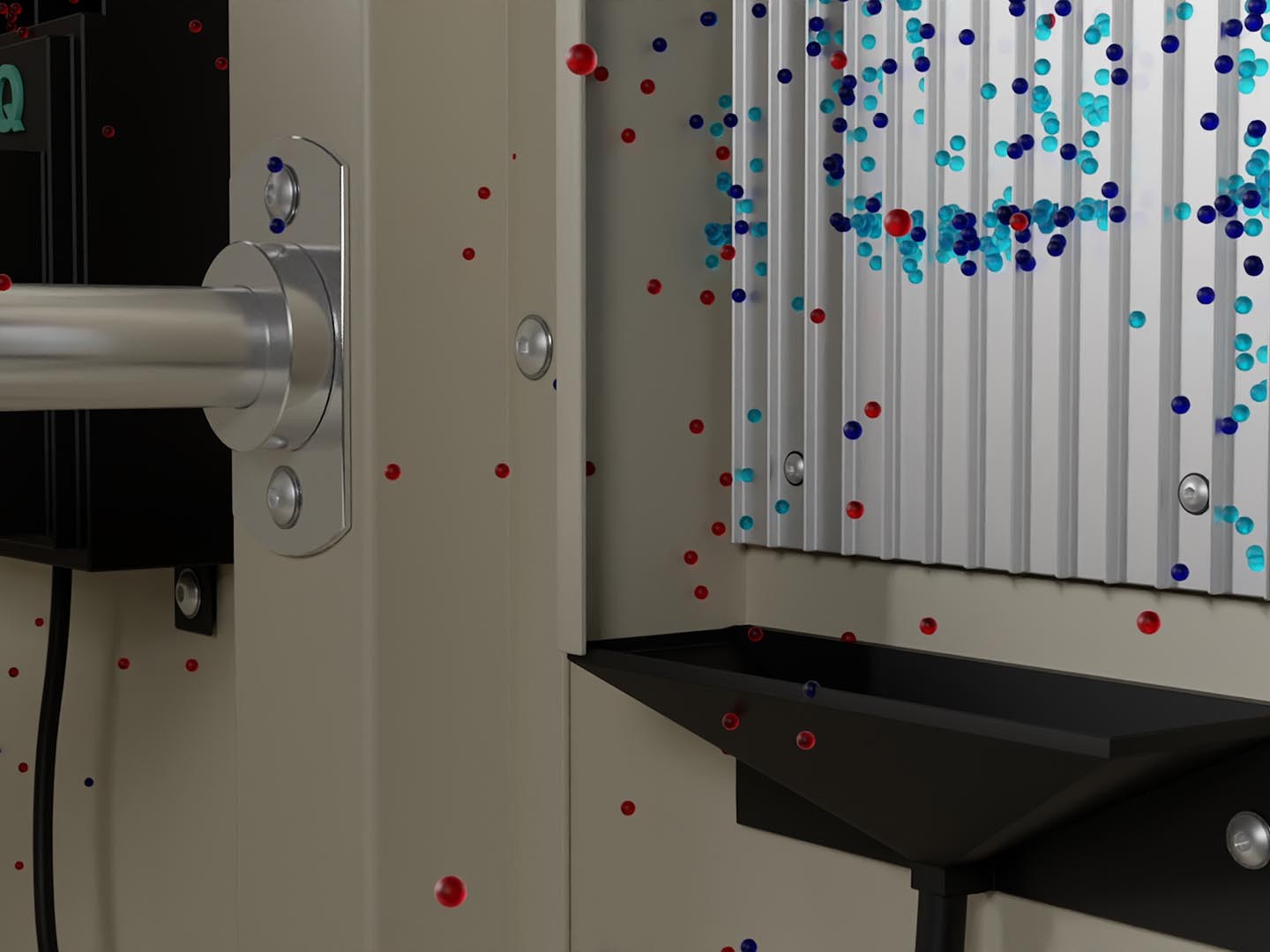

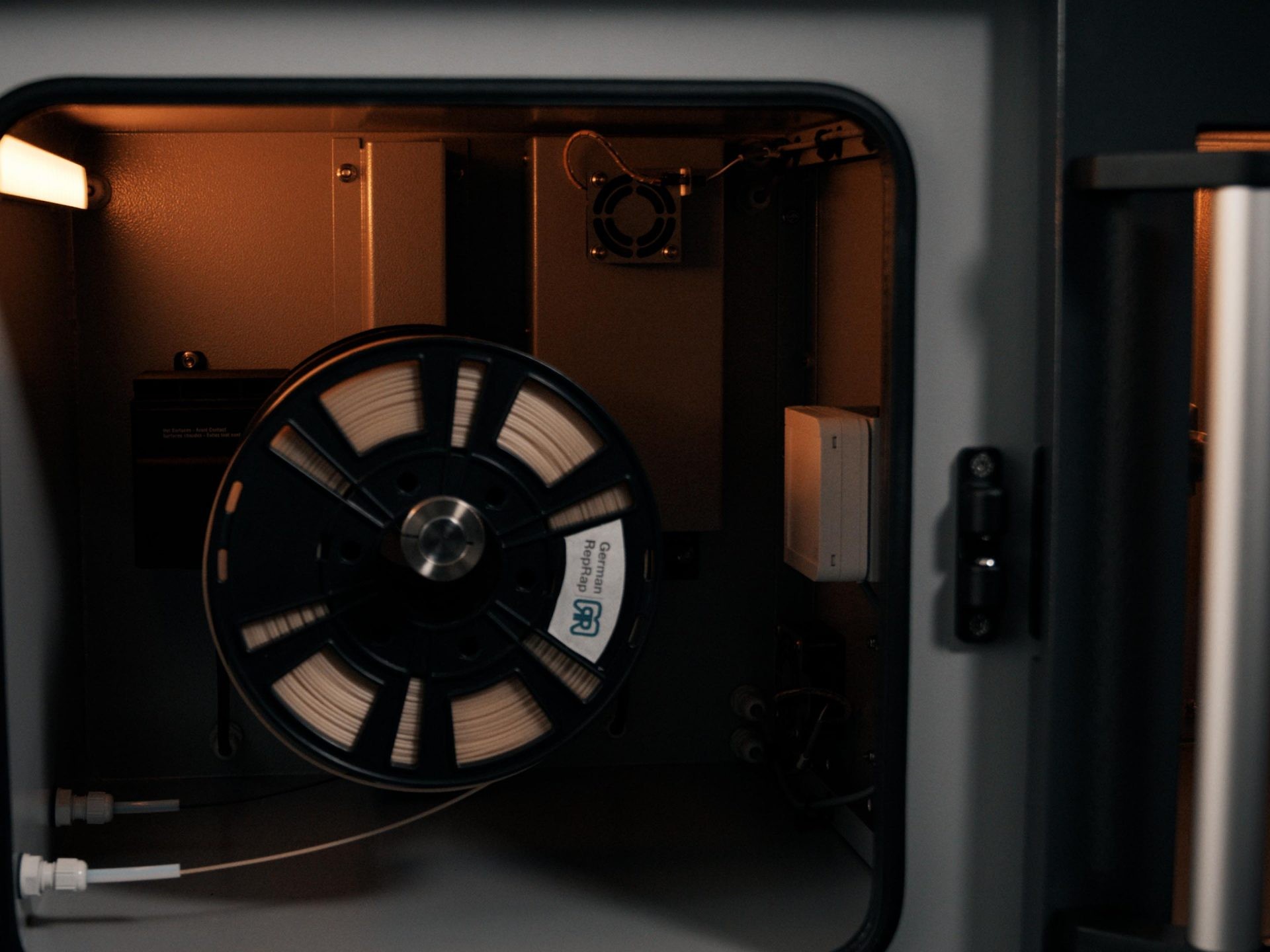

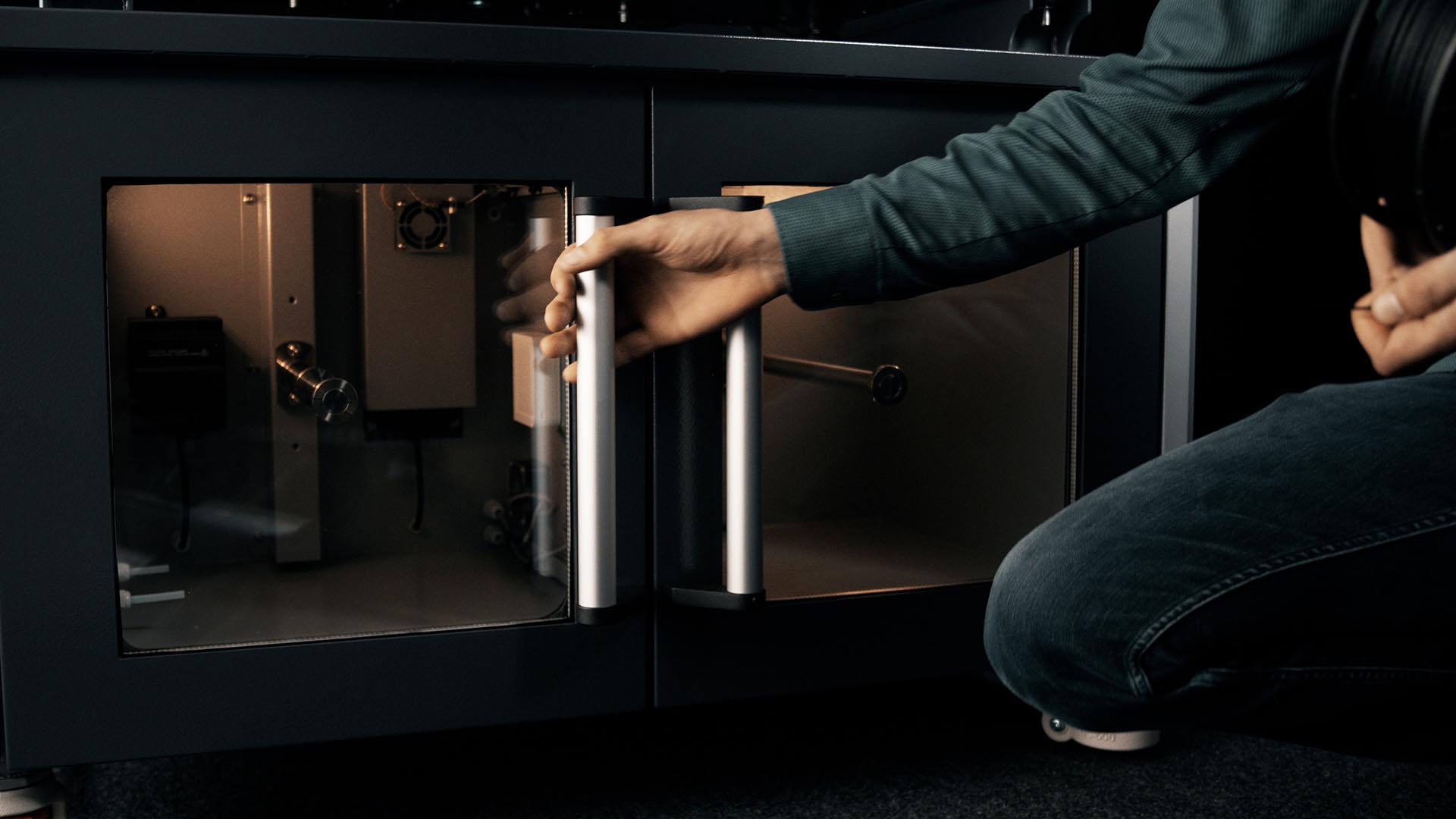

The MiQ 5 is the new material drying unit from innovatiQ. Designed as a base cabinet, the dryer also functions as a storage chamber for the filament material. The material is fed internally into the print head in an encapsulated process.

Drying is a recognized upstream process in 3D manufacturing to better process plastic filaments.

In additive manufacturing, it is important that the filament remains “dry” throughout the entire printing process. InnovatiQ has chosen the most sophisticated method with the MiQ 5 to bring the filament to an optimal state prior to extrusion.

Technical data

This means that the improved properties of the filament are constantly maintained. For this purpose, innovatiQ has developed the innovative MiQ 5 material drying unit for the TiQ 5 3D printer.

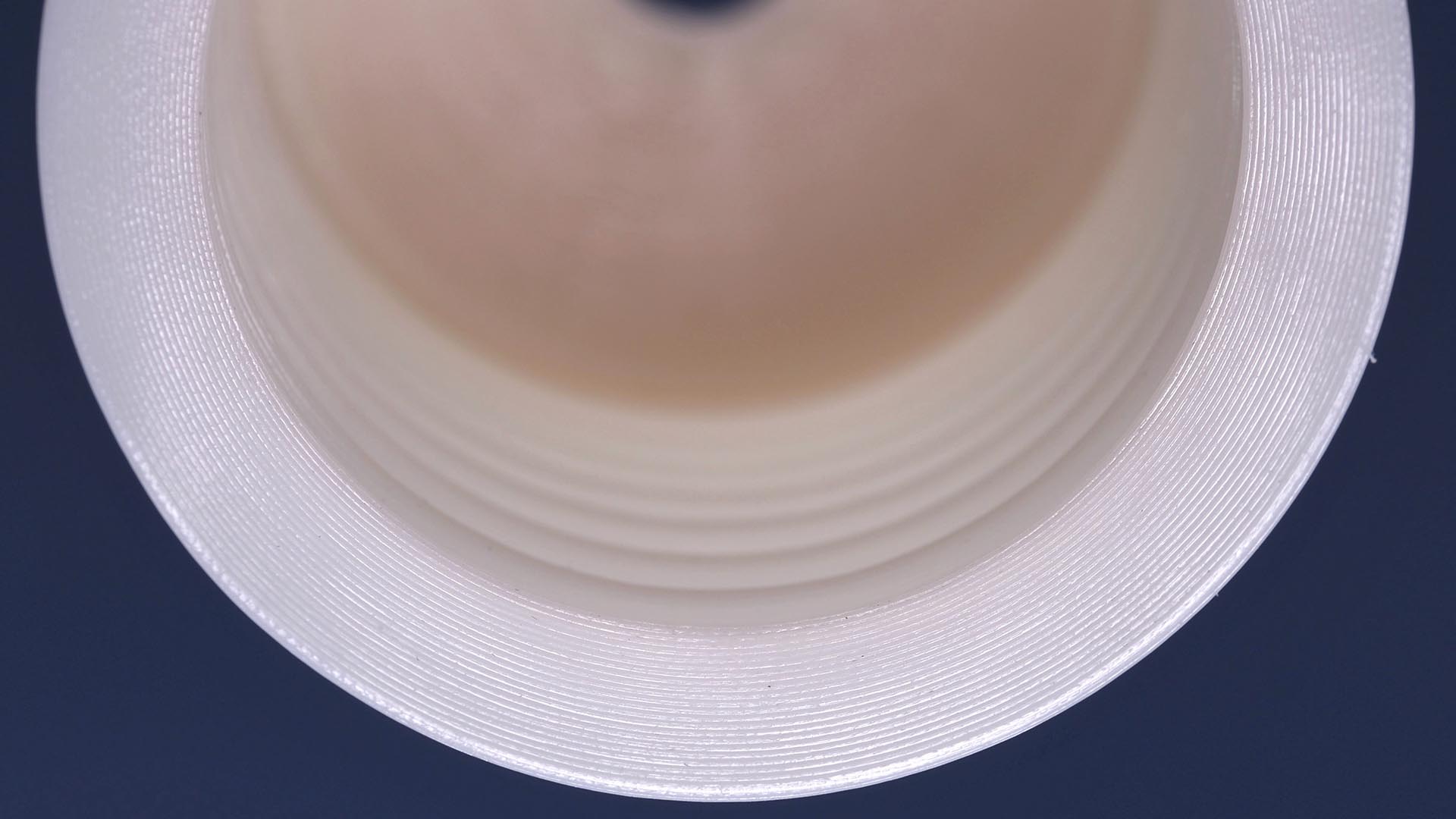

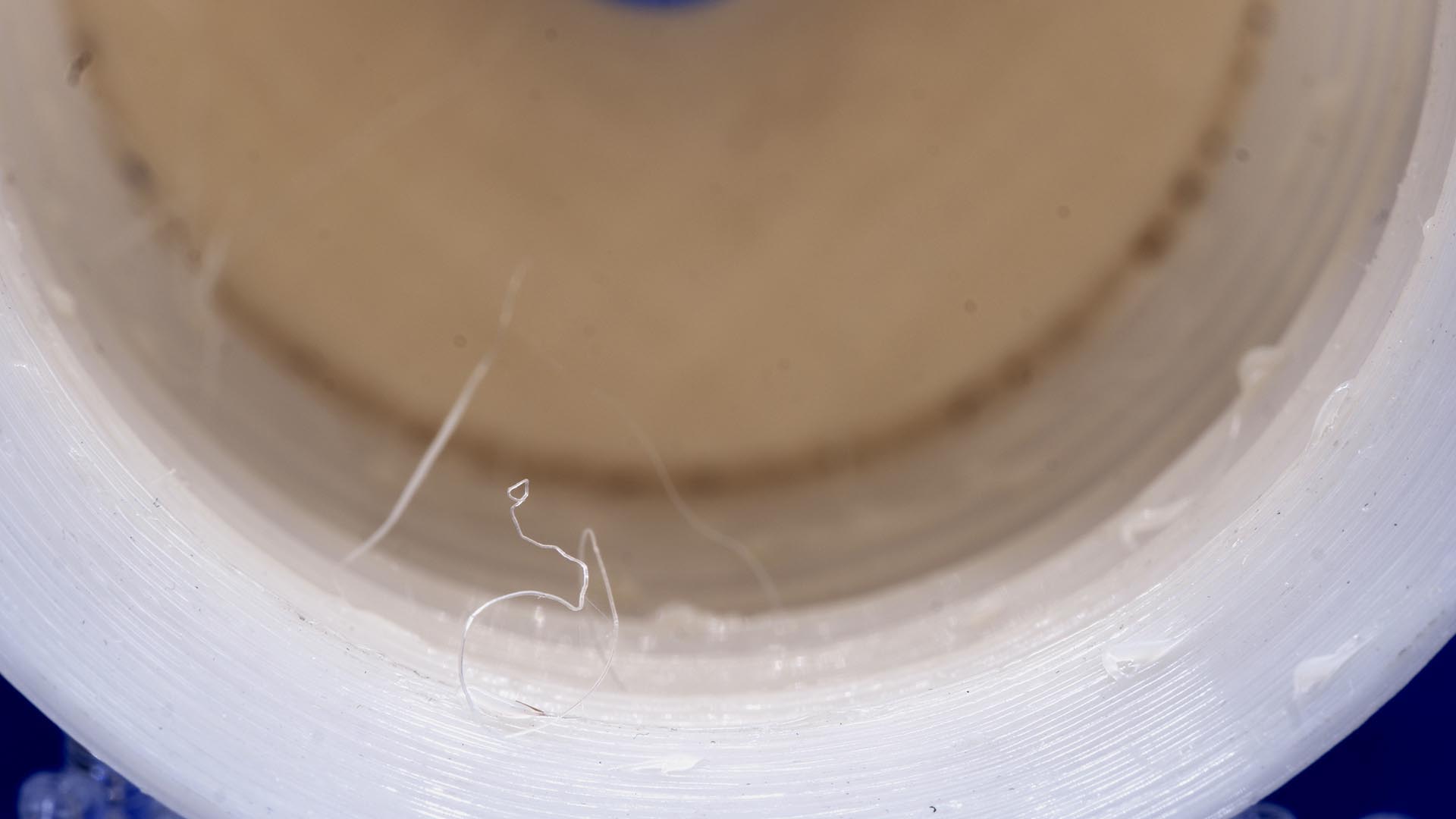

Image above: additively manufactured component with upstream material drying by the MiQ 5.

Image below: the same additively manufactured component without upstream material drying.

Technical Features

- Humidity: < <8 % and 4 %

- Material intake print area:one spool per extruder = 2

- Material intake storage area 5 small or 3 large spools

- Power consumption: 0.3 kW, approx. 50 % in continuous operation 230 V, 16 A

- Voltage: 230 V, 16 A

- Filament diameter: suitable for all

- Material (filament): all hydrophilic filaments

- Operating temperature: max 55 °C in the material chamber

- Network connection: stand-alone dryer

- Outer dimensions (W/D/H): 1134 x 726 x 643 mm

- Weight: approx. 115 kg

- Technology: Material drying

Service & Support

Would you like a personal consultation or an individual offer for this system?

With pleasure! Contact our Service & Support Team for a personal handling of your request.

Materials compatible with this system:

Nothing found.