TiQ 2 – compact 3D printer for industrial applications from fiber-reinforced materials

Outstanding standard equipment of the TiQ 2

The TiQ 2, with an installation space of 330 x 330 x 300 mm, is a 3D printer specially developed for so-called mass customization, i.e. personalized volume production. Thanks to innovatiQ’s proprietary dual extruder technology, it is particularly suitable for processing fiber-reinforced materials. At the same time, it is very easy to operate thanks to the so-called SmartFunctions. SmartFunctions in the TiQ 2 are auxiliary and operating commands integrated in the control system that make operating the machine child’s play while helping to prevent failures. The easy handling makes the TiQ 2 a reliable companion in your production.

Compact class – best economic efficiency!

The TiQ 2 shows its advantages particularly in the processing of fiber-reinforced (and thus very abrasive) materials for functional parts with long printing times. At the same time, it does not require an actively heated construction chamber, which makes it particularly economical in daily operation. A material drykeeping unit can be chosen optionally to prepare even hydrophilic materials for 3D printing. Material drykeeping increases process reliability but also the surface quality of the printed components.

The TiQ 2 is equipped with all the features you need to succeed in additive manufacturing. The standard scope of supply includes:

- GestiQ Pro: intuitive CNC control with integrated SmartFunctions

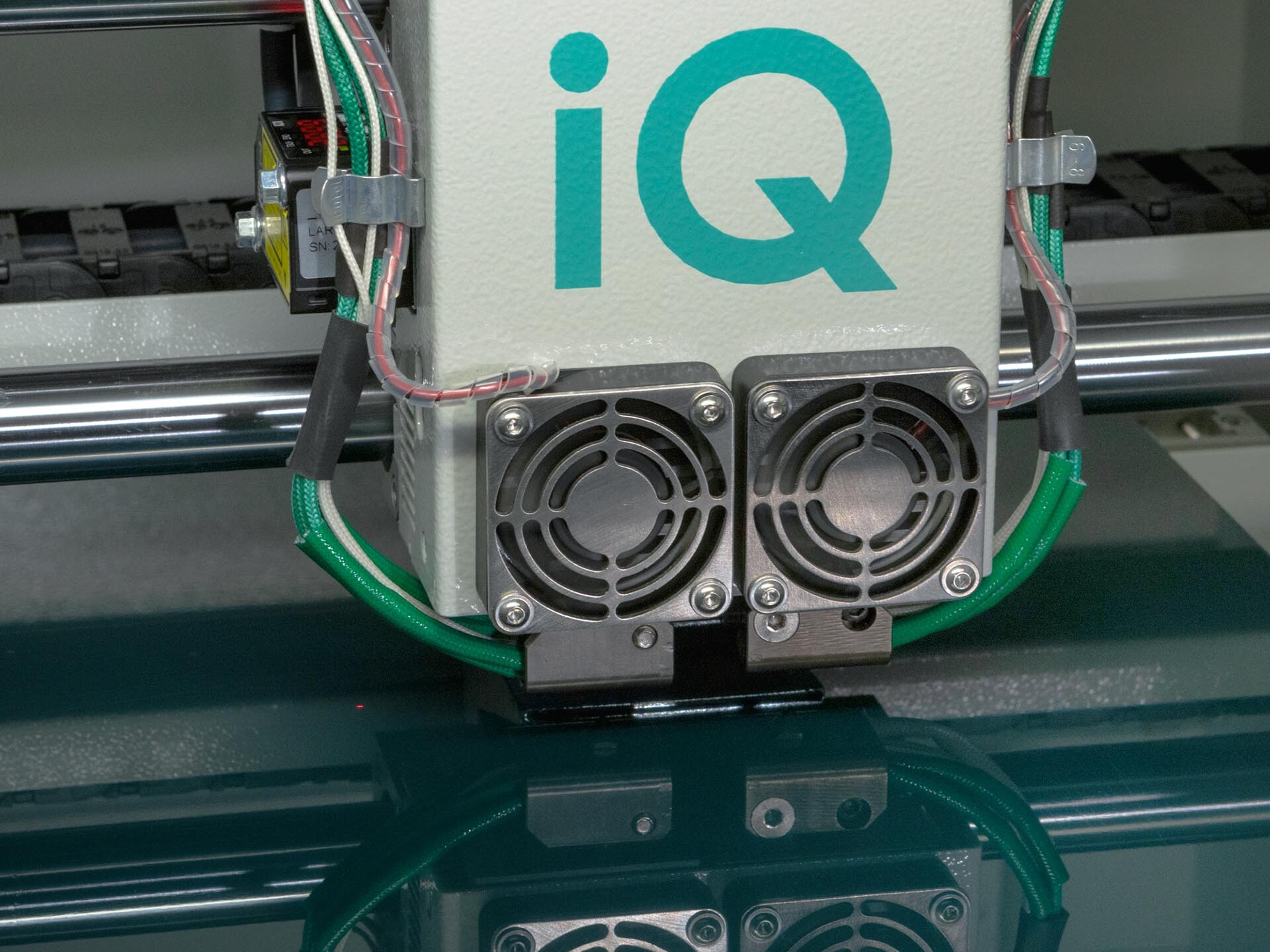

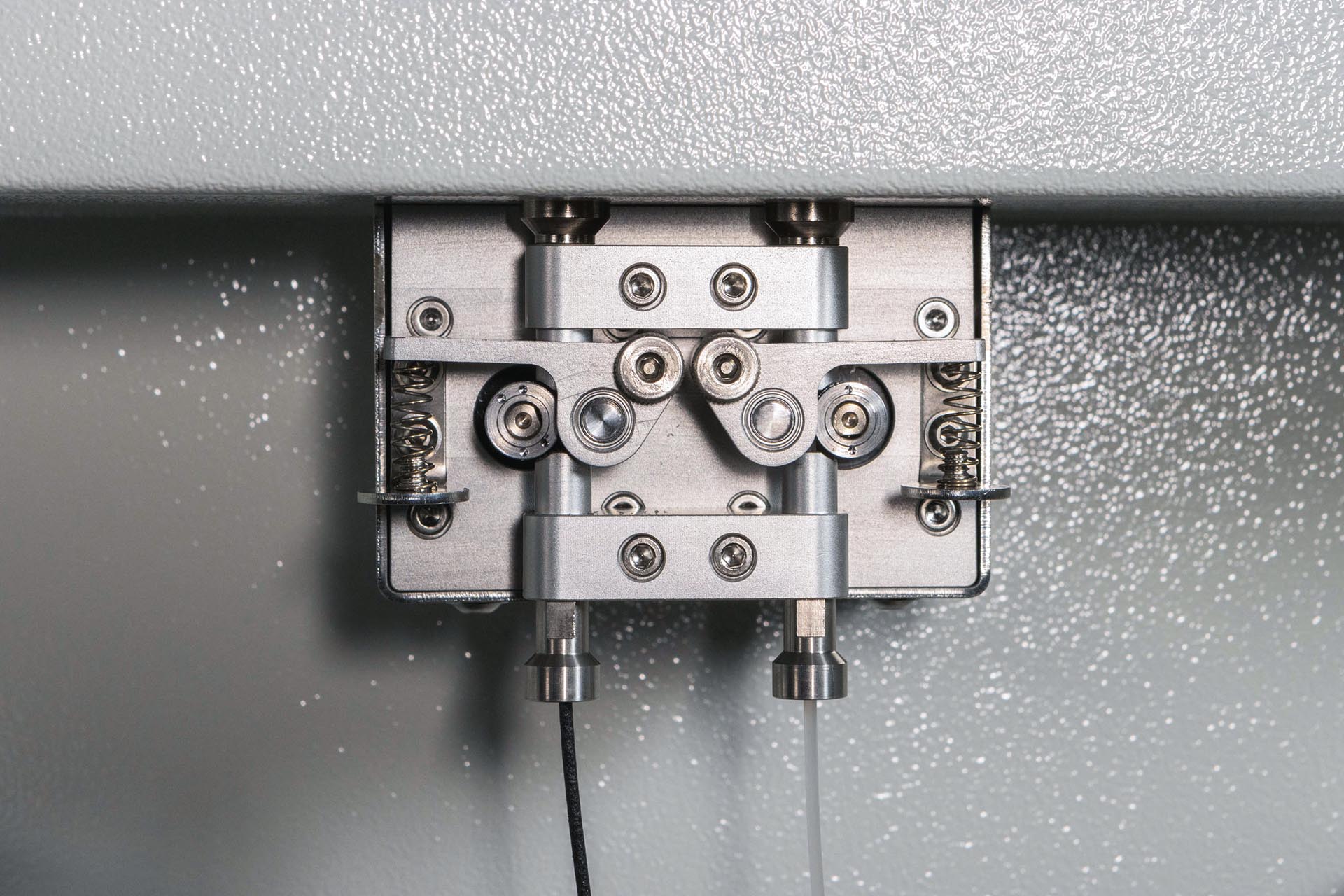

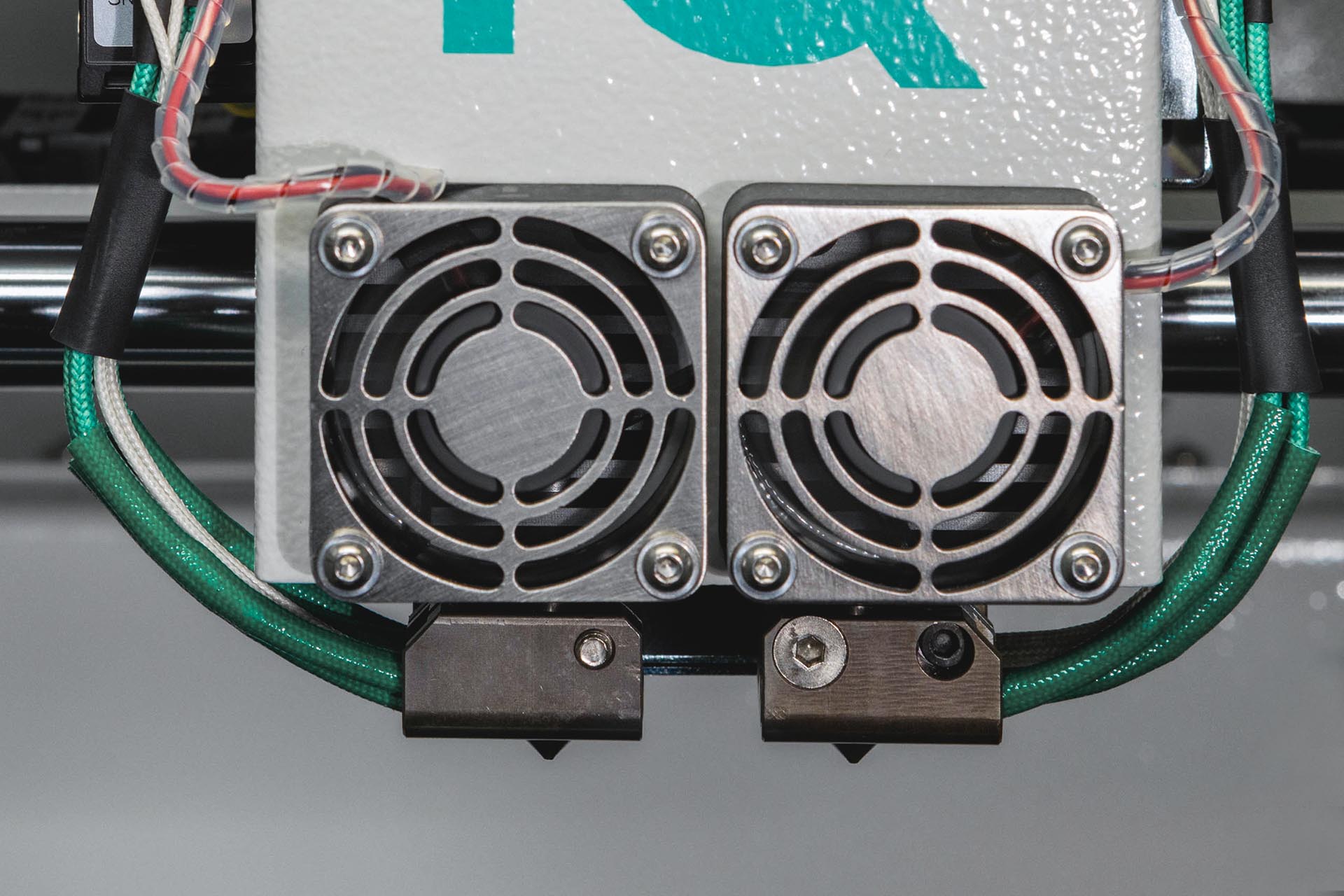

- QuadDrive dual printhead up to 300° C for many hard/soft materials

- MonoLift extruder for collision-free operation

- In-house developed nozzle technology for continuous operation

- Automatic mesh bed leveling

- Optional: Material Dry Keeping Unit, OPCUA, SmartMonitoringSystem, Build Chamber

Camera, High Temperature Extruder Package

Technical features

GestiQ-Pro is the CNC-based interface from innovatiQ. It supports the intuitive operation of the 3D printer with its SmartFunctions

SmartFunctions: the irreplaceable helpers from innovatiQ for a reliable printing process.

The strengths of innovatiQ’s proprietary printhead technology come into their own when processing fiber-reinforced, abrasive materials.

Technical data

- Built chamber (X/Y/Z): 330 x 330 x 300 mm

- HMI: GestiQ-Pro with 7-inch-Touch-Display, network capable

- Print speed*: 10 – 250 mm/s

- Travel speed*: Positioning 10 – 300 mm/s

- Accuracy (X/Y): +/- 0,02 mm

- Layer thickness* (min.): 0,1 – 0,6 mm – depending on chosen nozzle

- Filament- / Nozzle-Diameter: 1,75 mm

- Standard Nozzle: 0,40 mm, optional: 0,25 / 0,60 / 0,80 mm

- Extruder: QuadDrive with Mono Lift

- Temperature Extruder: up to 300° C

- Temperature Printbed: 140 °C

- Nozzle calibration: yes

- Mesh-bed leveling: yes automatically

- Data exchange: stand-alone printing with touch display or network-compatible

- Slicer-Software: included

- Power consumption (max.): 1.2 kW, approx. 30 % in continuous operation

- Power Supply: 230 V, 6 A (EU); 110 V, 10 A (US)

- Status lamp: integrated light bar with message status

- Dimensions (W/D/H): 920 x 689 x 908 mm

- Weight: ca. 165 kg (without drying-unit)

- Technology: FFF (Fused Filament Fabrication)

- Optional: Material Drykeeping Unit, OPC-UA, SmartMonitoring-System

* Deviations depending on geometry/material/process