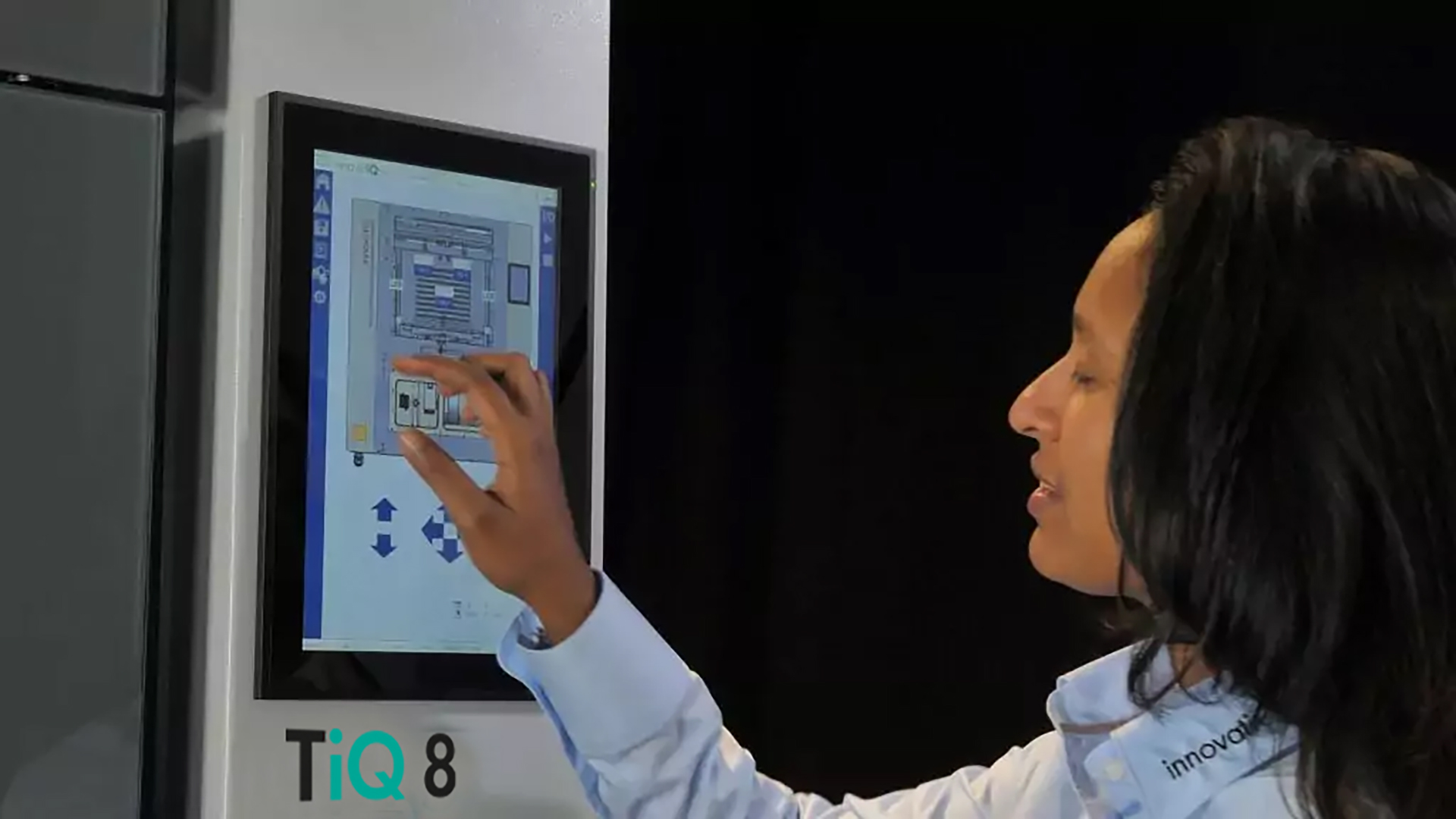

GestiQ-Pro is the new Human Machine Interface (HMI) from innovatiQ. The innovative industrial control supports the user with integrated SmartFunctions.

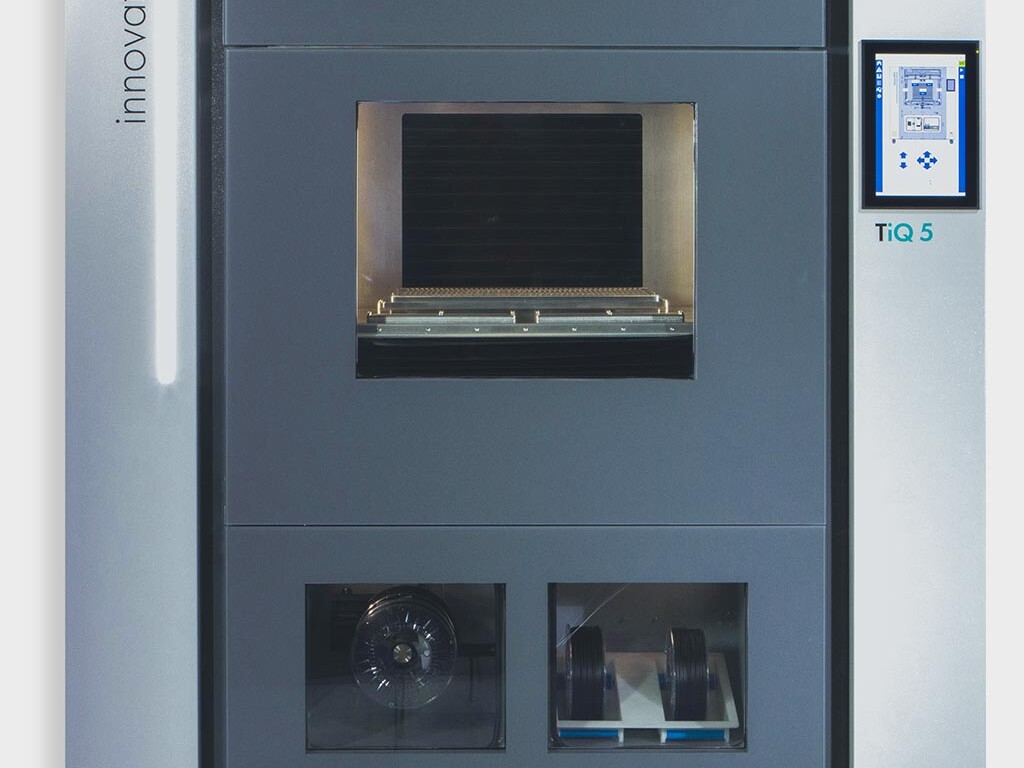

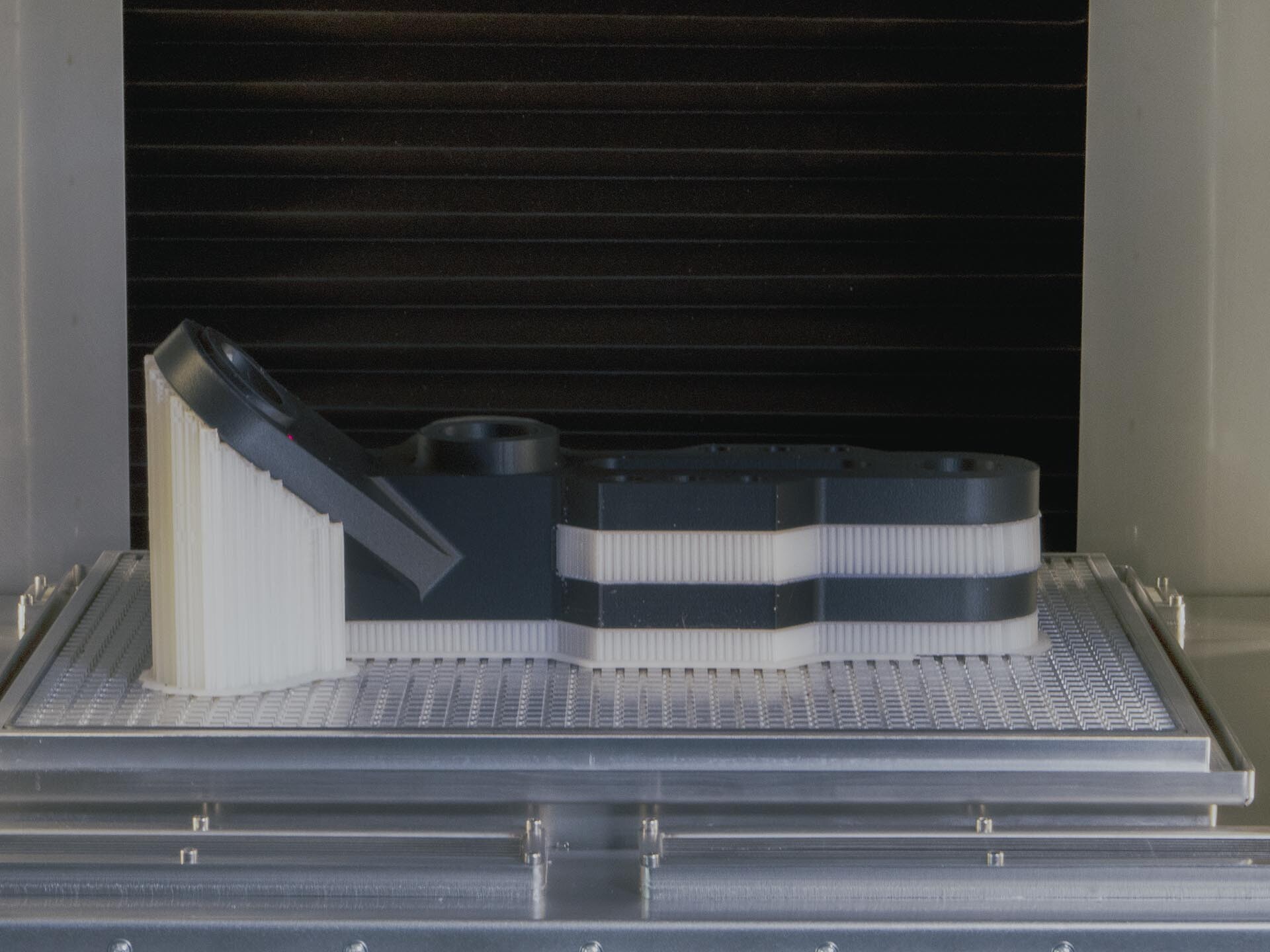

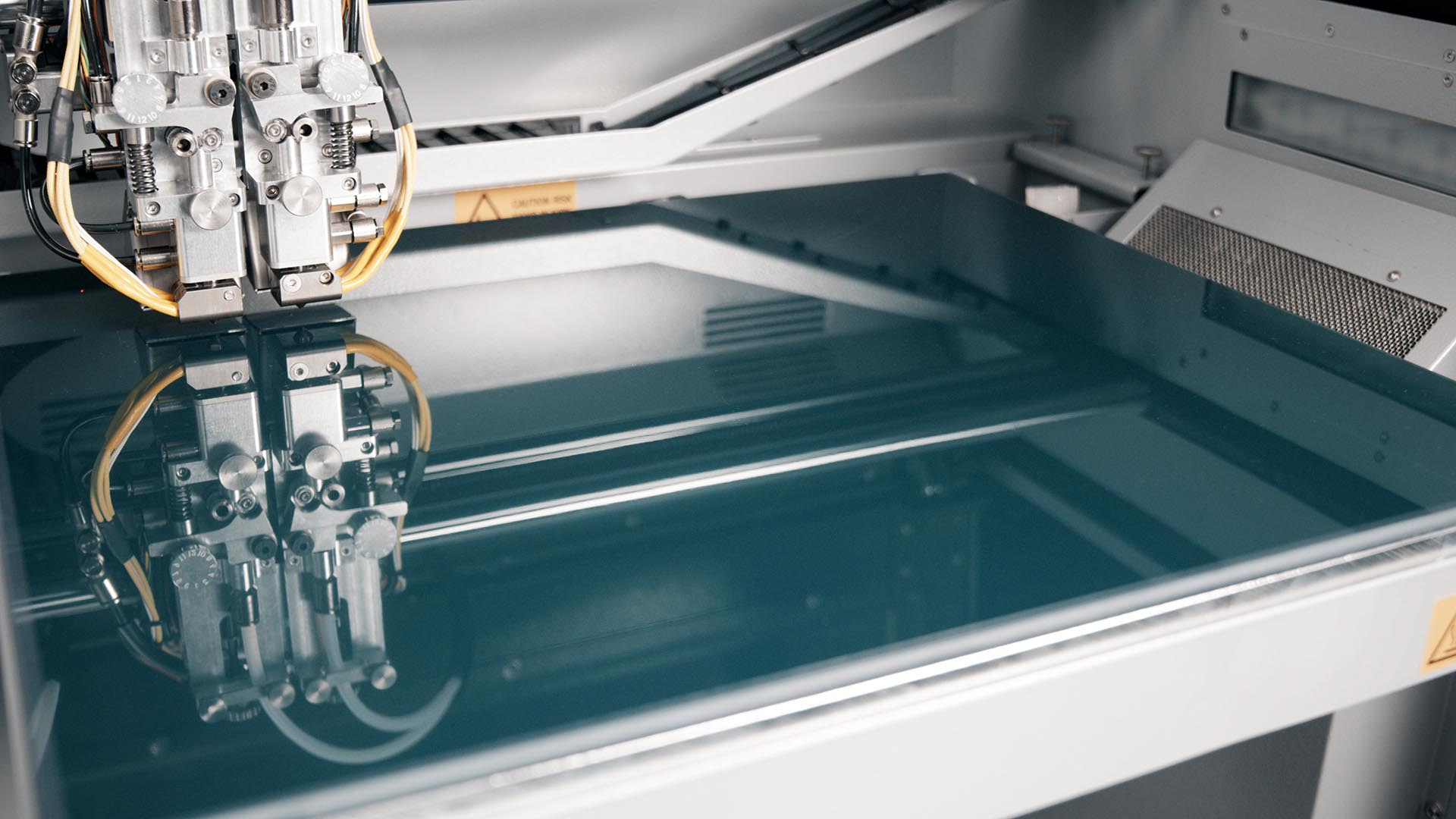

90 liters process reliability. Dimension and reliability combine in the vacuum process chamber of the TiQ 5 Pro.

Technical features

GestiQ-Pro is the new CNC interface from innovatiQ. The innovative industrial control supports the user with integrated SmartFunctions.

SmartFunctions: the irreplaceable helpers from innovatiQ for a reliable printing process.

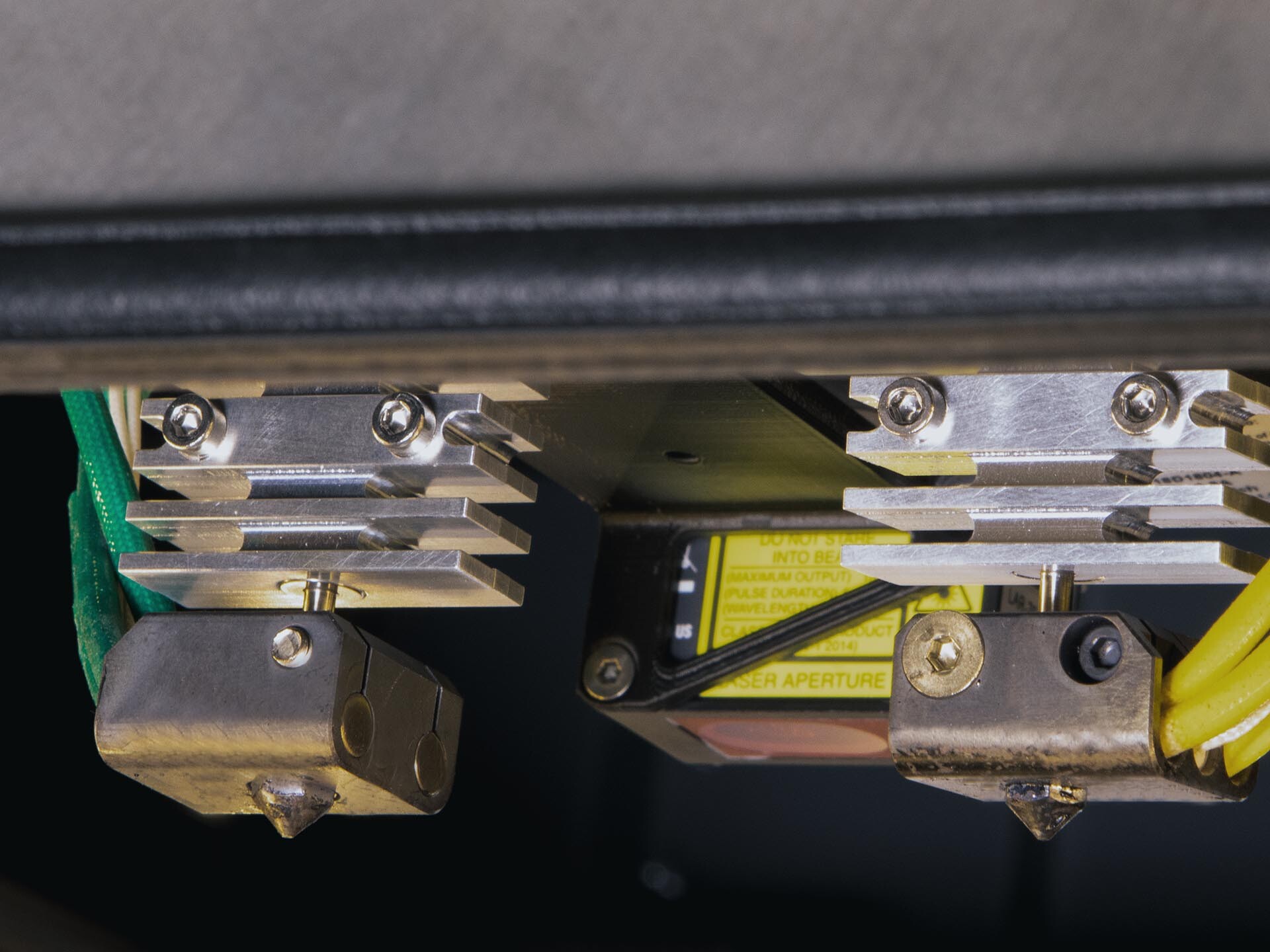

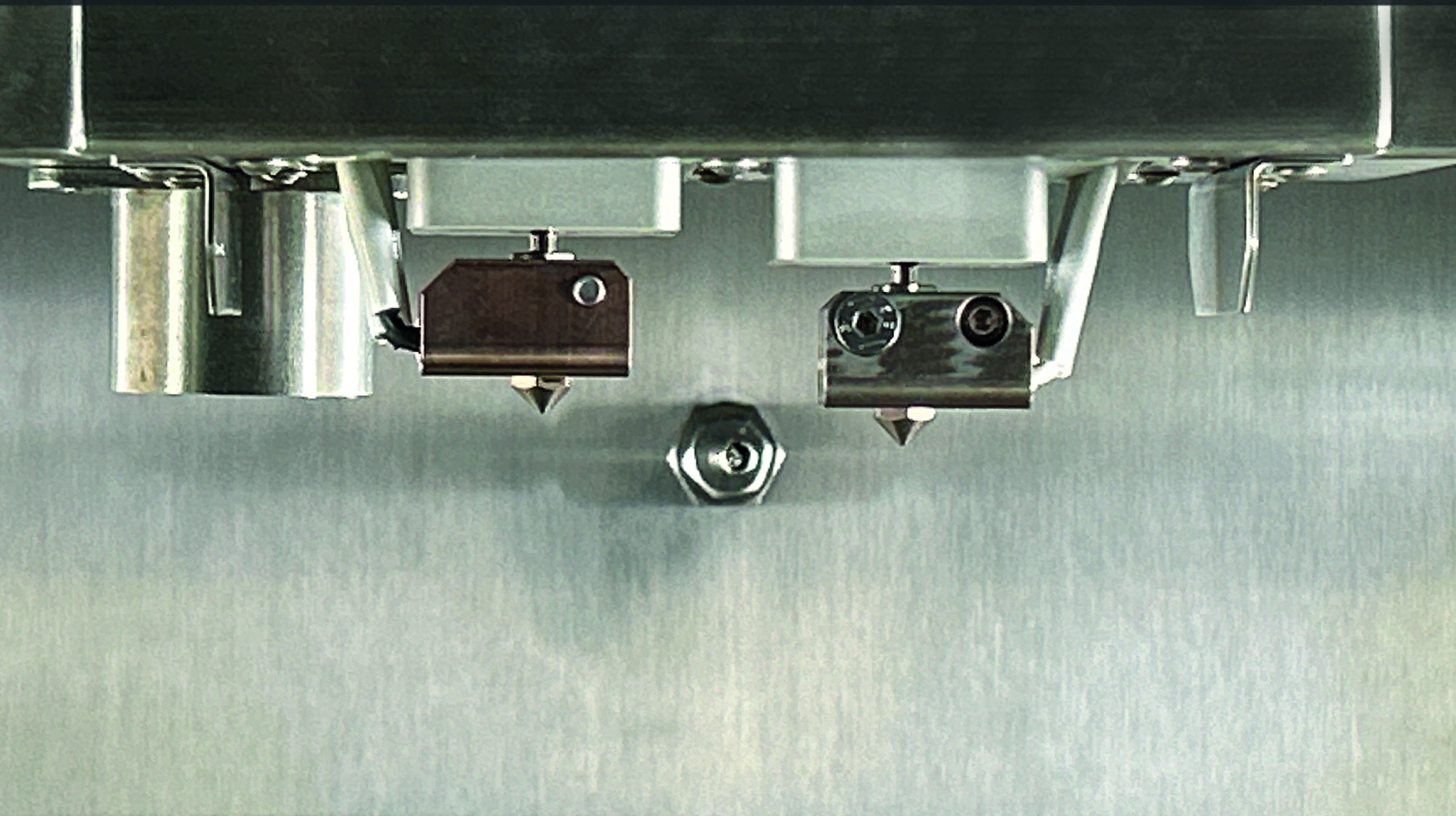

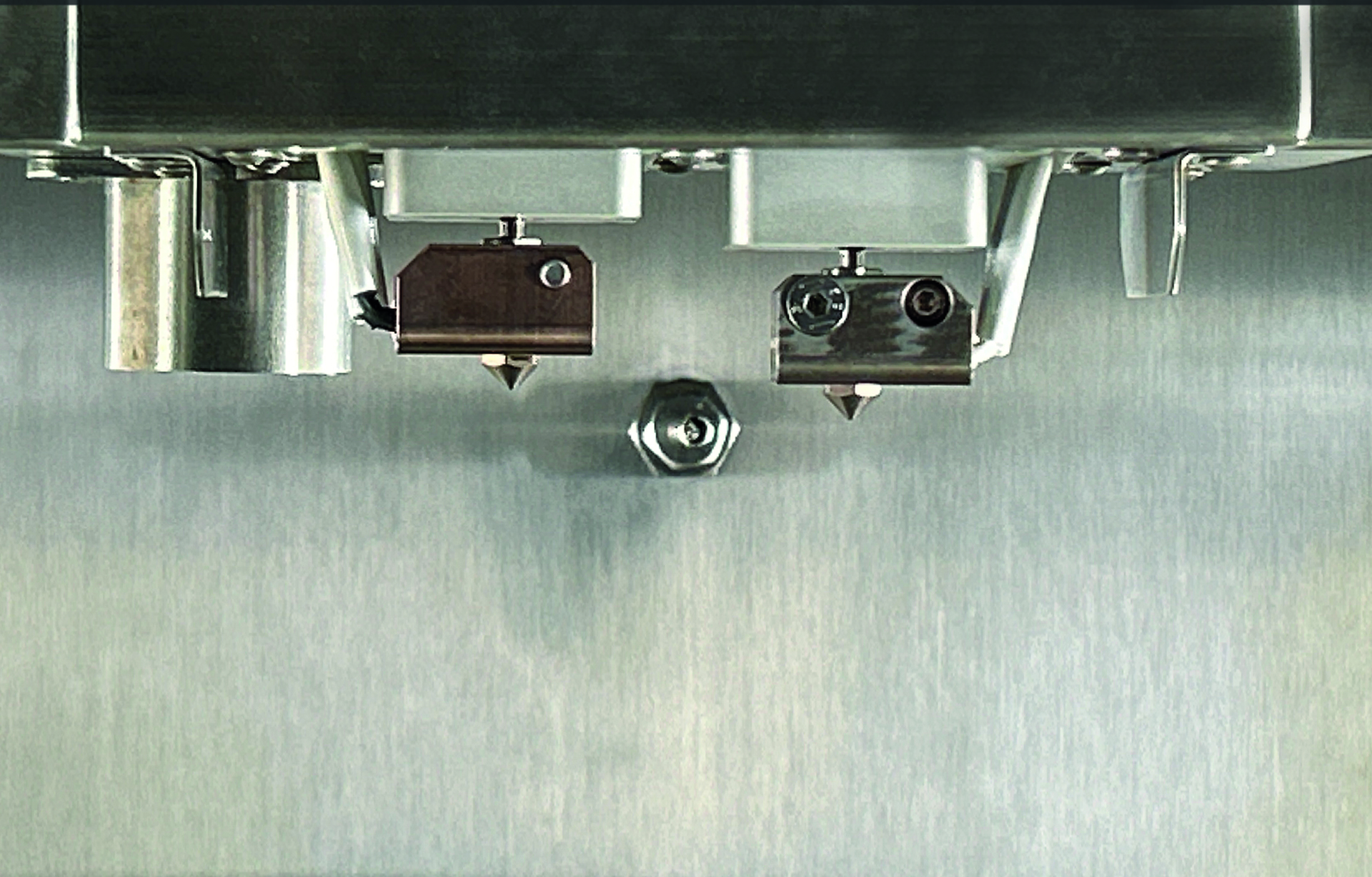

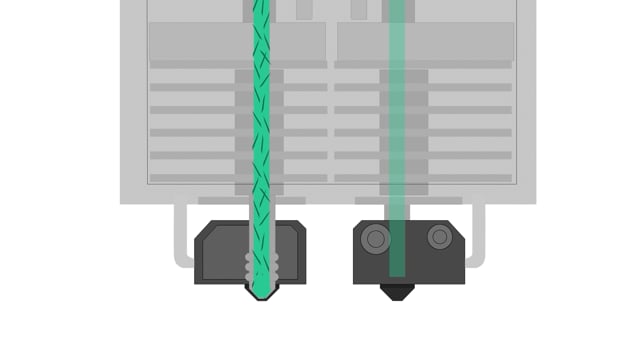

The “CoreLine” printhead technology developed by innovatiQ is suitable for many material combinations. CoreLine enables dual printing with maximum precision and safety.

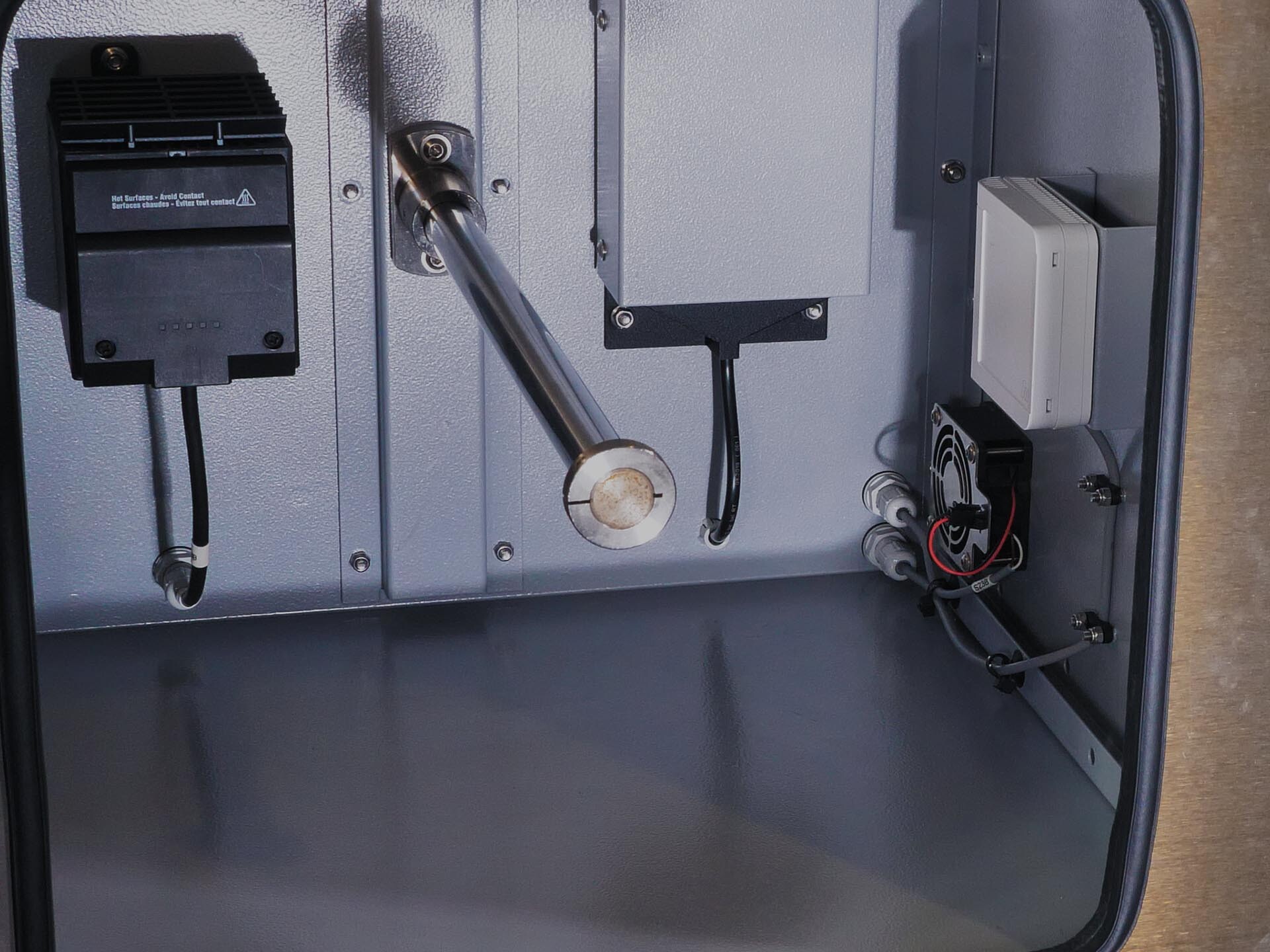

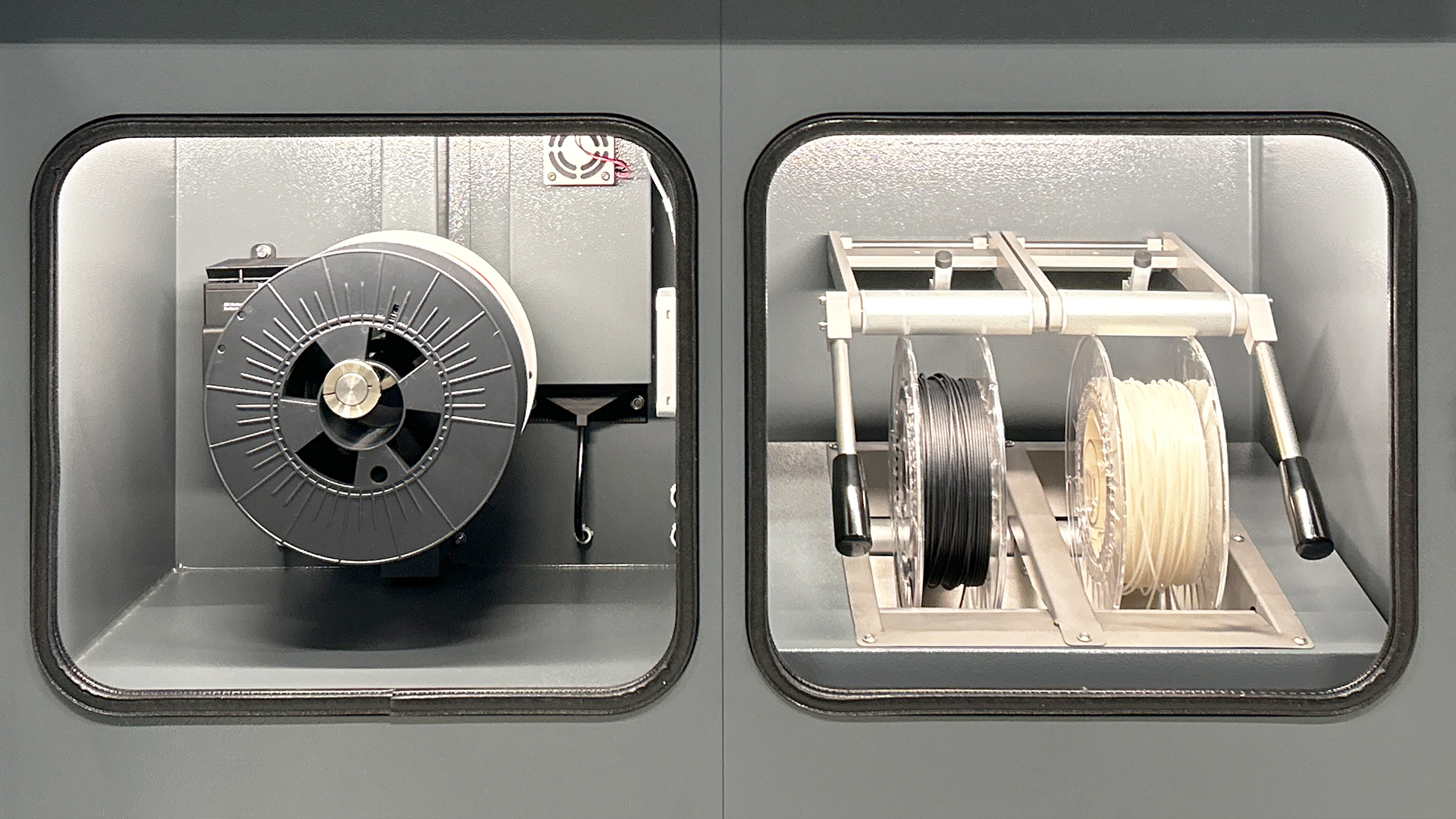

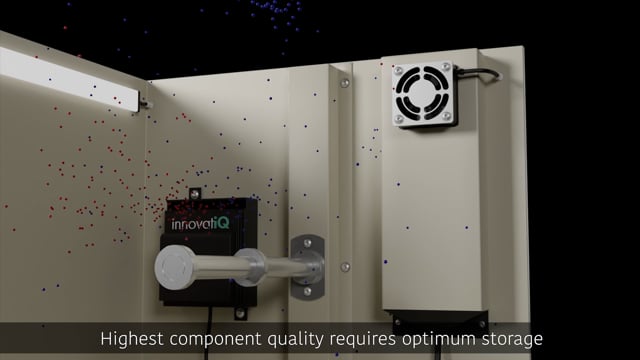

The highest component quality requires optimum storage and maximum possible drying during the printing process. The integrated material drying unit in the TiQ 5 Pro ensures both and works completely autonomously.

Technical data

- Build chamber (X/Y/Z): 500 x 400 x 450 mm

- HMI: GestiQ-Pro with 12-inch-Touch-Display, network capable

- Print speed*: 10 – 180 mm/s

- Travel speed*: Positioning 10 – 300 mm/s

- Accuracy* (X/Y): +/- 0,1 mm

- Layer thickness* (min.): 0,1 mm

- Filament diameter: 1,75 mm

- Nozzle options: 0,40 mm / 0,60 mm / 0,80 mm

- Extruder: CoreLine Technology up to 400 °C

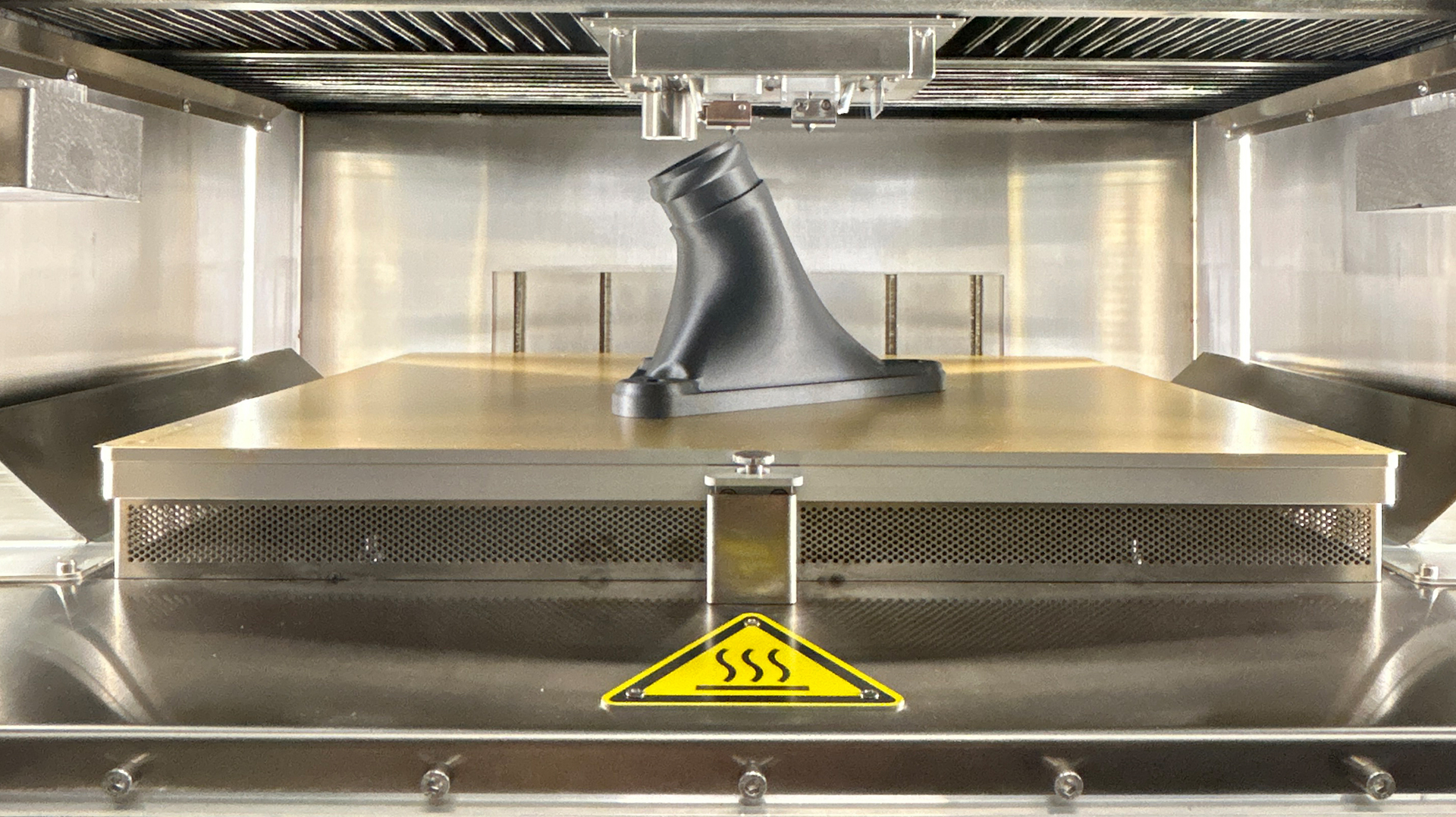

- Active build chamber: actively heated up to 155 °C

- Printing plate: Vacuum printing bed heatable up to 155 °C

- Nozzle calibration yes, automatic

- Mesh-bed leveling, yes

- Data connection: Stand-alone printing with touch display or network capable,

- Software-Slicer: Simplify3D

- Power consumption (max.): 7.5 kW

- Connected load: 400 V, 16 A (EU)

- Status lamp: integrated light bar with message status

- Dimensions (W/D/H): 1480 x 1091 x 1875 mm

- Weight: ca. 800 kg

- Technology: FFF (Fused Filament Fabrication)

- Drying unit: 5 storage places + 2 processing places

- Optional: SmartMonitoring system

* Deviations depending on geometry/material/process