QUALITY

The quality of innovatiQ's 3D printers is an indispensable benchmark throughout the entire production process. From development to design, production and assembly, quality control through to installation and commissioning, the high requirements for long-term reliable use in an industrial environment must be guaranteed!

CONSTRUCTION & DEVELOPMENT:

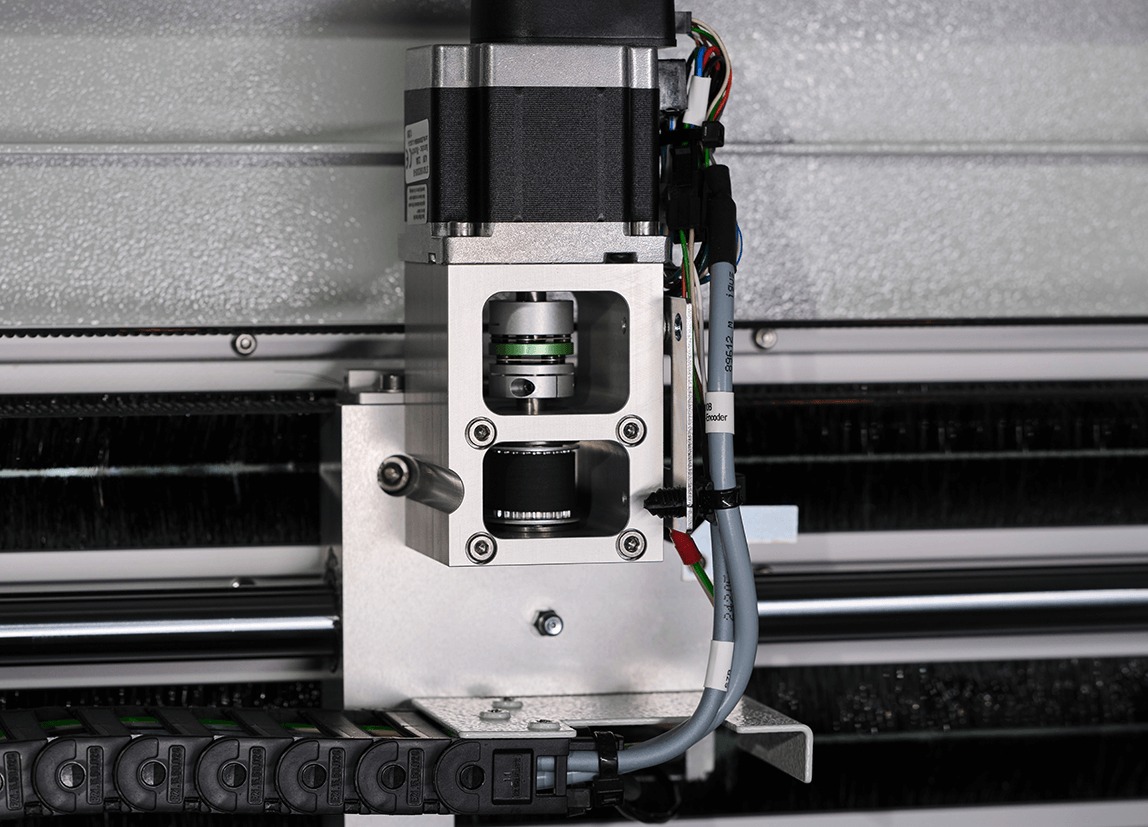

The development of the printers follows a clear focus on quality, process reliability and repeatability. With temperature-stable dual extruders suitable for high temperatures, wear-resistant nozzles and precise direct drives, InnovatiQ offers one of the most robust print head technologies in the FDM sector and ensures high mechanical stability and consistent print quality, even at high temperatures.

MECHANICAL ENGINEERING & MATERIALS:

InnovatiQ 3D printers stand for genuine mechanical engineering quality that is specially designed to meet the high demands of industrial applications. This quality is reflected in the robust and durable design, the precise mechanics and the reliable control technology. All components are designed to work stably and safely even in continuous operation under demanding conditions - a decisive advantage when it comes to production reliability and consistently high component quality.

Thanks to the solid mechanical engineering quality, InnovatiQ 3D printers achieve outstanding dimensional accuracy and repeatability, which is particularly important for functional end components, precise prototypes or accurately fitting fixtures. The closed design, high-quality linear guides and precise temperature control ensure that even large components can be produced without distortion and with uniform layer quality.

CONTROL & SOFTWARE:

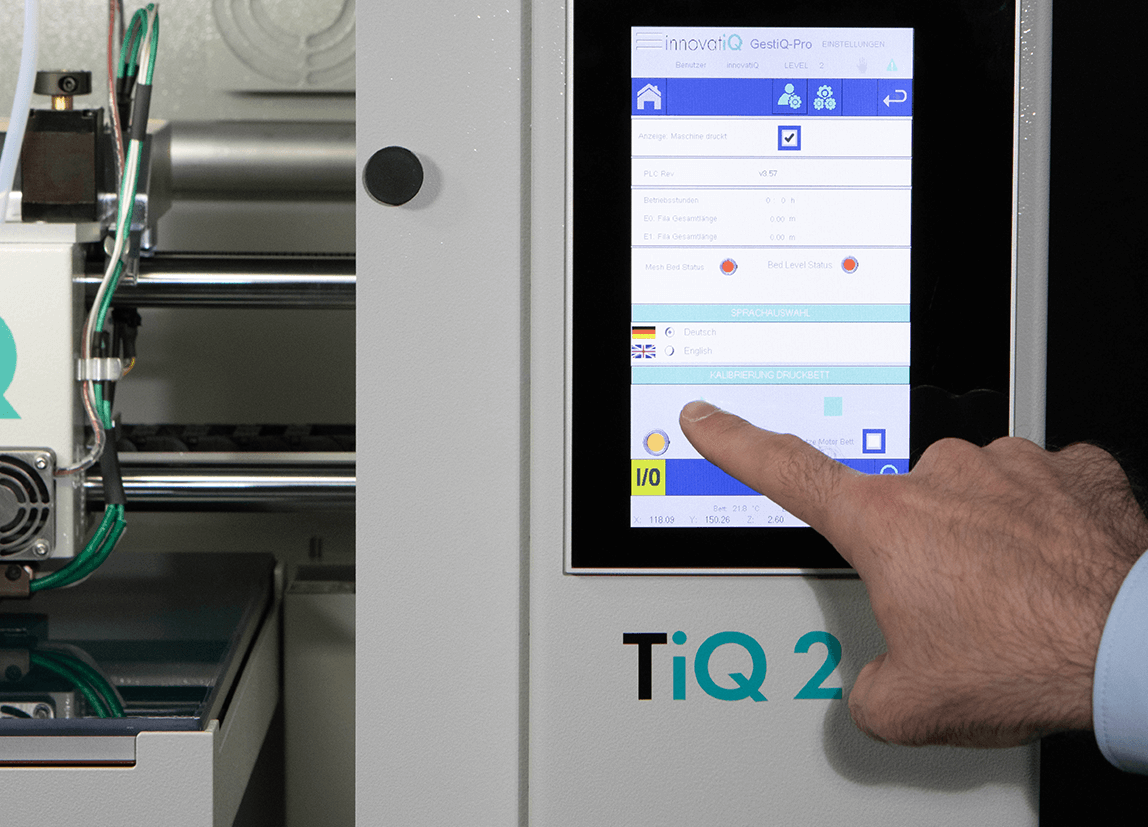

The software and control systems of innovatiQ's 3D printers offer numerous advantages that are specifically tailored to the needs of industrial users. They make a decisive contribution to ensuring that the printers are not only easy to operate, but also reliable, precise and process-safe.

A key advantage is the intuitive user interface of the GestiQ control system, which offers clear, easy-to-understand menu navigation. This means that even users without in-depth prior knowledge can get started quickly and safely. Functions such as guided set-up and maintenance wizards further simplify operation and reduce sources of error, while role-based access control is also possible.

The software and control of the innovatiQ 3D printers offer decisive advantages: high user-friendliness, maximum process control, material flexibility, quality assurance and industrial integration. They therefore provide companies with optimum support in integrating 3D printing into their processes as a reliable, productive and economical technology.

HOTENDS & NOZZLES:

The dual print heads of the innovatiQ FDM printers are equipped with high-quality, abrasion-resistant hotends/nozzles made from a special tungsten-copper alloy. This makes them particularly durable and low-maintenance - a clear advantage in terms of reliability in long-term production use and a cost advantage for you in terms of operating costs.

Depending on the machine type, the print heads and nozzles with temperatures of up to 440° C are also ideally suited for processing high-temperature printing materials.

The control of the dual-head print heads ensures collision-free printing, even with combined printing processes with different materials.

MEASUREMENT TECHNOLOGY & SENSORS:

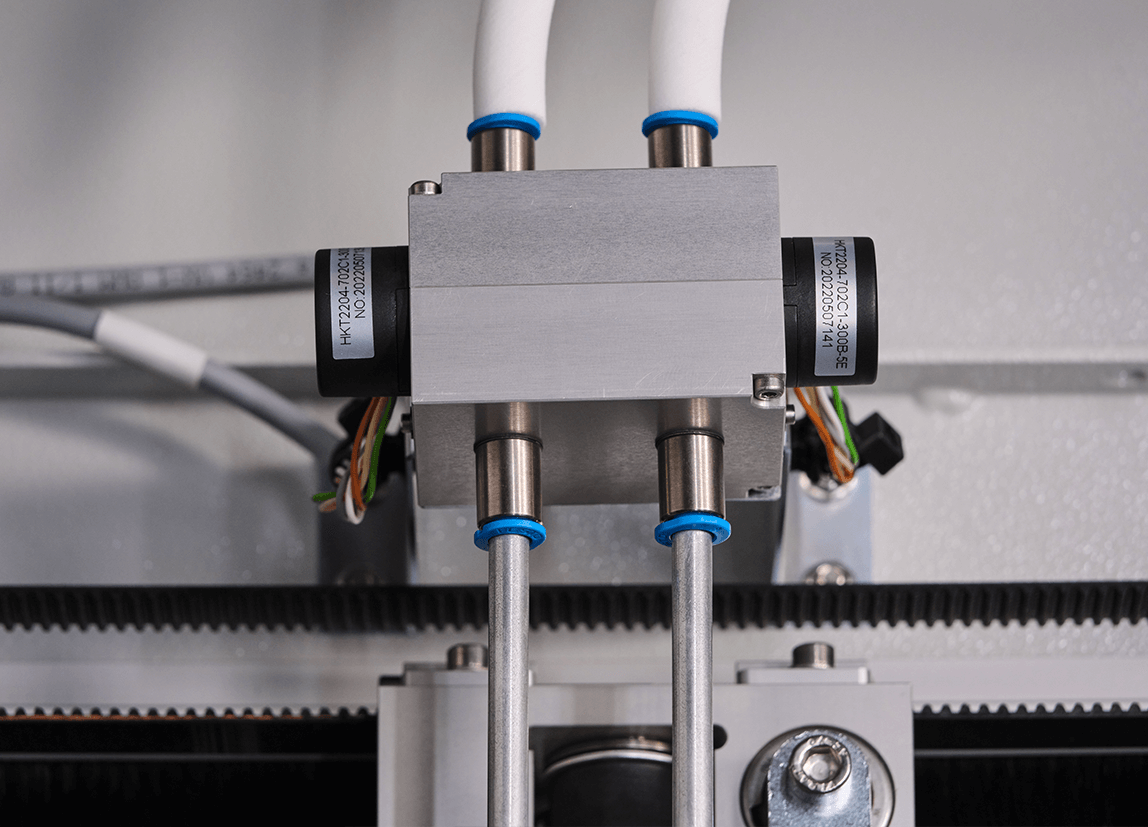

Thanks to the powerful control system, all pressure parameters are precisely monitored and regulated using sensors. Temperature curves, extrusion speed, cooling and installation space conditions are continuously monitored and automatically adjusted if necessary. This ensures consistently high component quality, even with complex geometries or large print jobs.

Smart functions such as SmartTrack and SmartSpeed automatically control the material feed with sensor support and automatically adjust the feed and print speed to the current filament requirements. This makes a decisive contribution to process reliability, print quality and optimum print speed.

SAFETY:

QUALITY ASSURANCE:

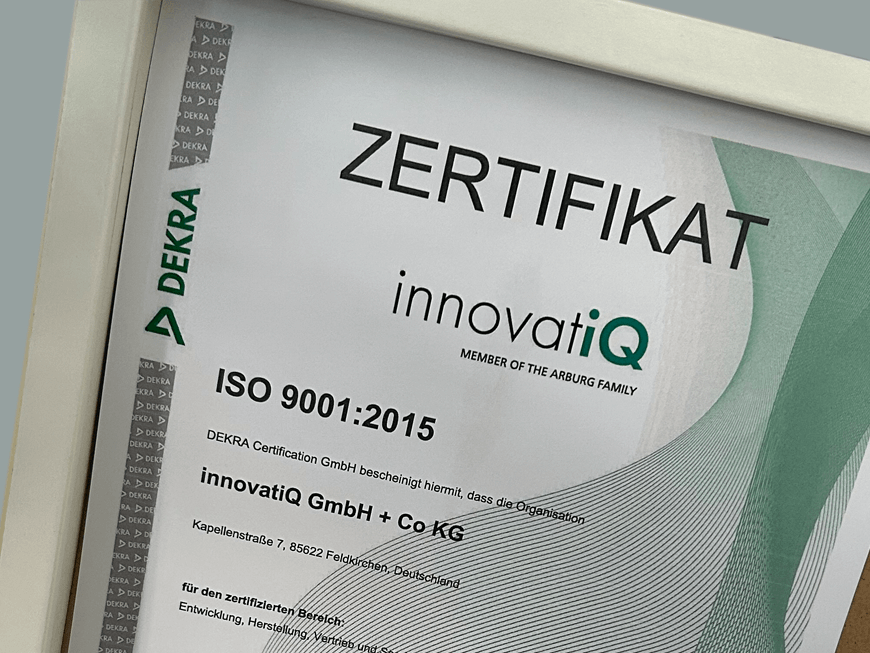

The development, production, sales and service of the innovative innovatiQ printers are subject to quality management and are certified in accordance with DIN ISO 9001:2015.

Our in-house quality assurance ensures compliance with our high quality standards through regular audits, monitoring and training.

COMPONENTS & PARTS

ELECTRONICS

Precise wiring and high-quality components with simultaneous safety: the electrical connections and circuits are completely protected by RCDs, for example.

DRIVES & AXLES

The robust milled axles are driven reliably and precisely by high-quality motors from renowned manufacturers. Power is transmitted using tried-and-tested, low-maintenance components.

PRINT HEAD & HOTENDS

The high-quality dual print heads of the innovatiQ FDM printers are equipped with abrasion-resistant hot ends/nozzles made of a special tungsten-copper alloy.

MATERIAL SUPPLY

The reliable bimotor material feed is continuously monitored by sensors and controlled for the ongoing printing process. This ensures the ideal material supply to the print head at all times.

TEMPERATURE

Components such as heated print beds, active build chamber temperature control and active thermally assisted dehumidification ensure ideal temperatures for the respective printing processes tailored to the material.

FRONTS MADE OF SAFETY GLASS

The doors as temperature-relevant areas are made of safety glass, which, depending on the machine, is also actively ventilated and access-protected to prevent burns or the like.

DRY KEEPING & ACTIVE DEHUMIDIFICATION

The integrated materialdehumidificationunit (TiQ8) actively dehumidifies up to 55° C and keeps hydrophilic filament in the required dry state, which increases process reliability and supports the surface quality of the printed components.