INDUSTRIAL 3D PRINTING

Additive manufacturing for industrial use: innovatiQ's 3D printer products offer high-quality and reliable solutions for development, production and automation.

3D PRINTER TECHNOLOGY WITH INDUSTRIAL ENGINEERING QUALITY.

innovatiQ 3D printers are characterized by industrial precision, material and processing quality, an open material system and intuitive user guidance - based on the quality and experience of German mechanical engineering. They are particularly suitable for companies that want to establish additive manufacturing as an integral part of their production chain - even for demanding applications.

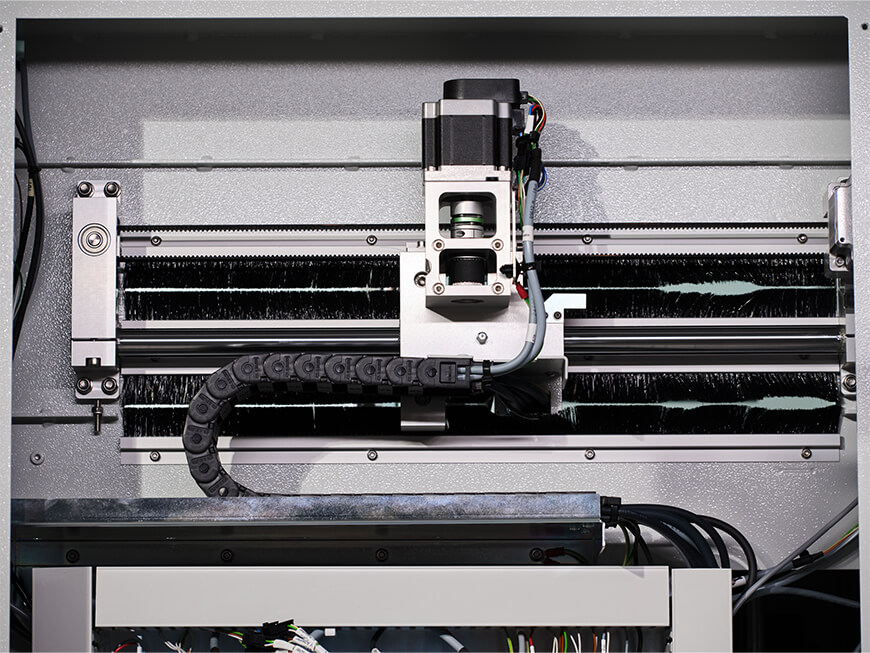

POWERFUL FFF 3D PRINTING.

innovatiQ's FFF printers offer you maximum performance, even for demanding applications!

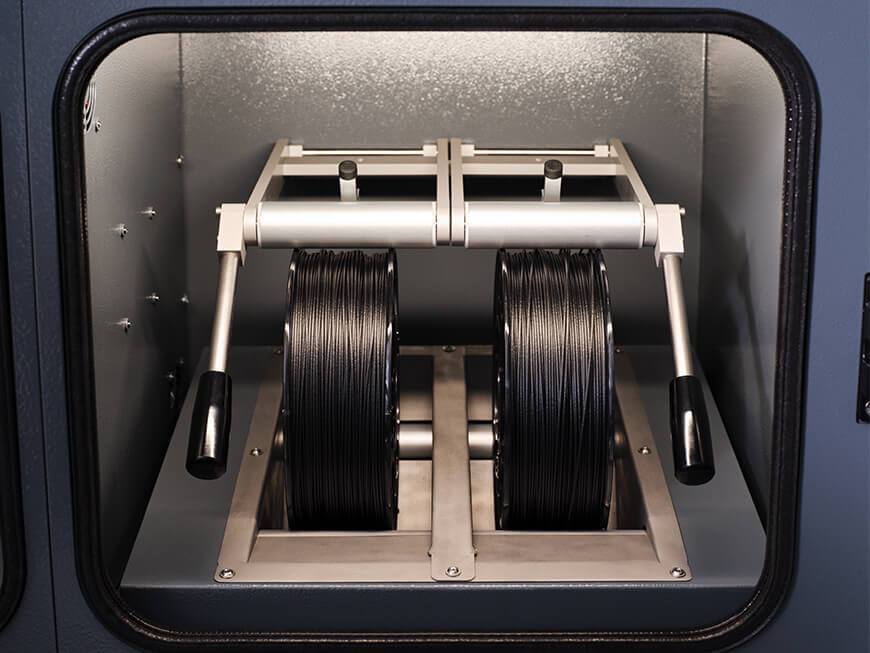

With precise processing, high repeat accuracy and the ability to reliably print both high-temperature materials and flexible materials such as TPU or extremely resistant fiber-reinforced plastics, the systems open up new dimensions in additive manufacturing. Whether prototype, functional part or series component - our printers reliably deliver impressive results.

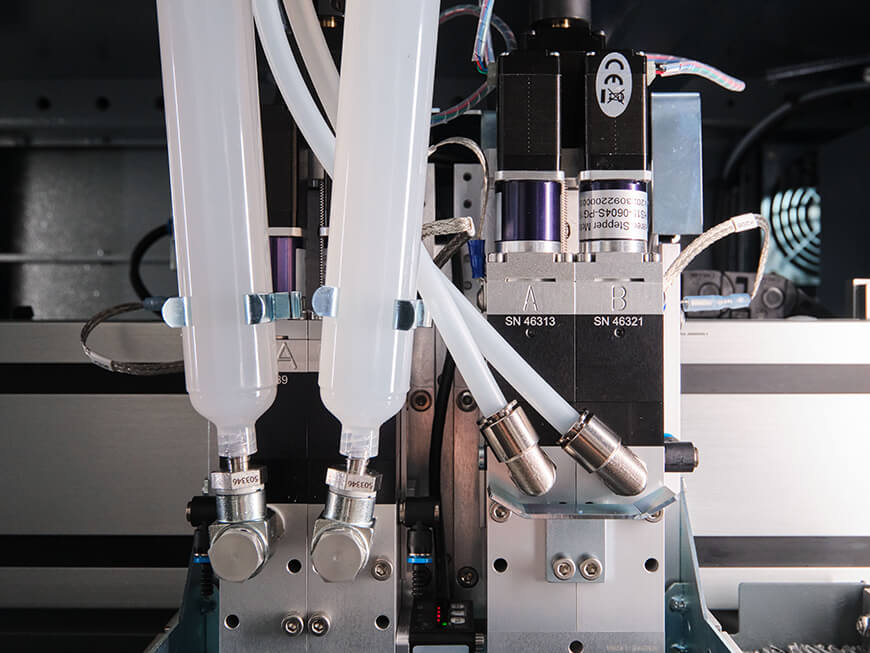

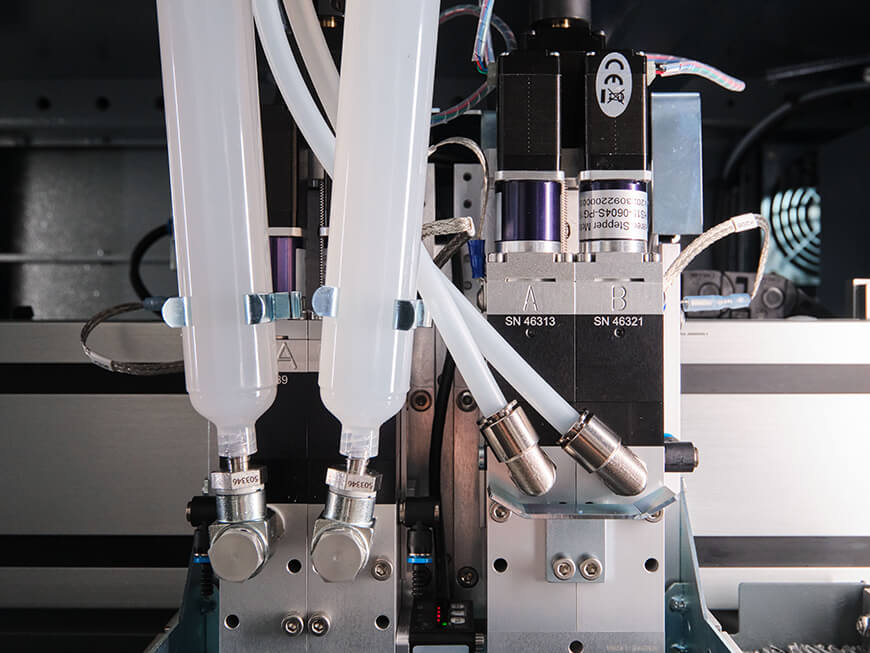

PATENTED LAM 3D PRINTING WITH

LSR INJECTION-MOLDED SILICONE

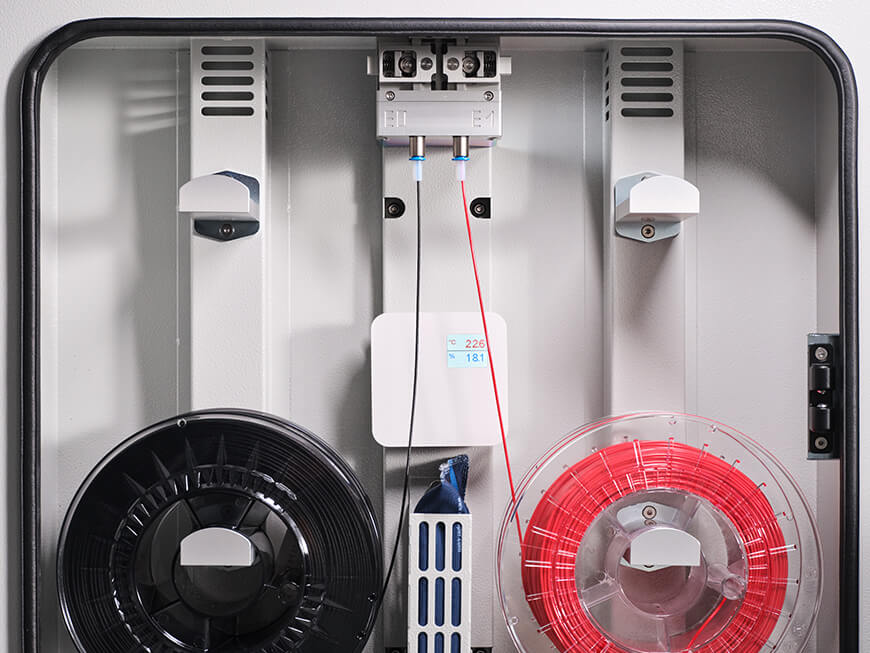

A second print head for printing with support material is now available as an option for the latest generation.

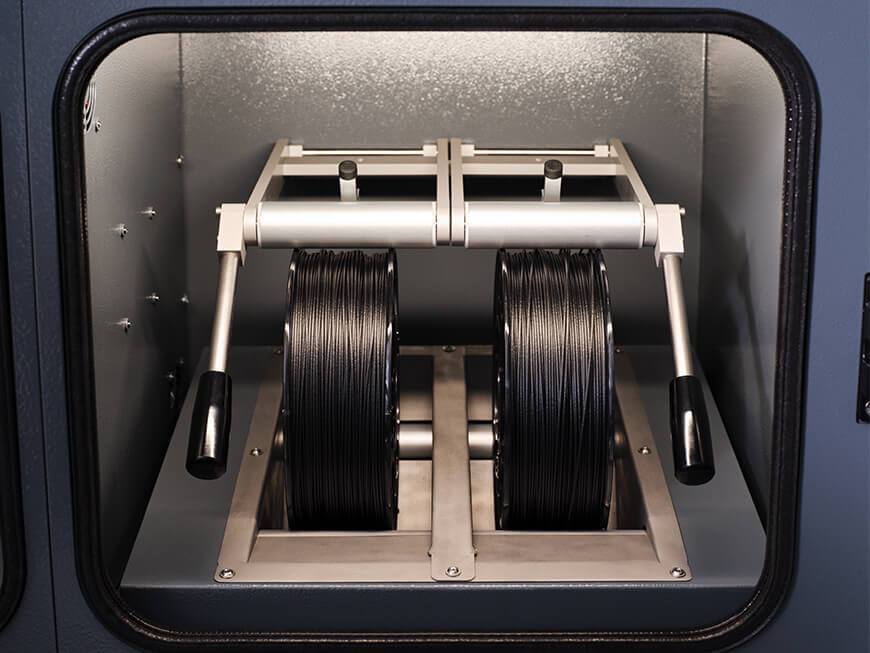

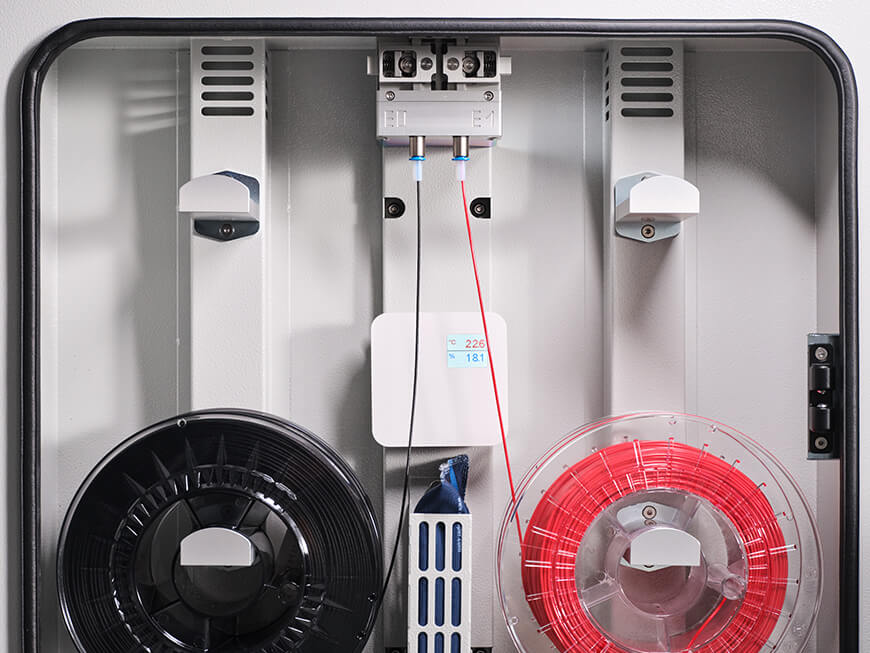

HIGH FLEXIBILITY & EFFICIENCY THANKS TO FREEDOM FROM MATERIALS.

The open material system of the innovatiQ 3D printers is ideal for anyone looking formaximum freedom, cost-effectiveness and future-proofing in additive manufacturing - especially in industrial, research-related or production-critical applications.

The material freedom of the innovatiQ printers offers the possibility (within the necessary technical specifications) to use the entire range of materials on the market for 3D printing. You are not tied to specific manufacturer material packages, but have the freedom to choose the most suitable and cost-effective material for your respective needs and projects. In addition, you can of course also access selectedmaterials that have been tested on innovatiQ printers, including validated profiles.

USER-FRIENDLINESS & SAFETY THANKS TO SMARTFUNCTIONS.

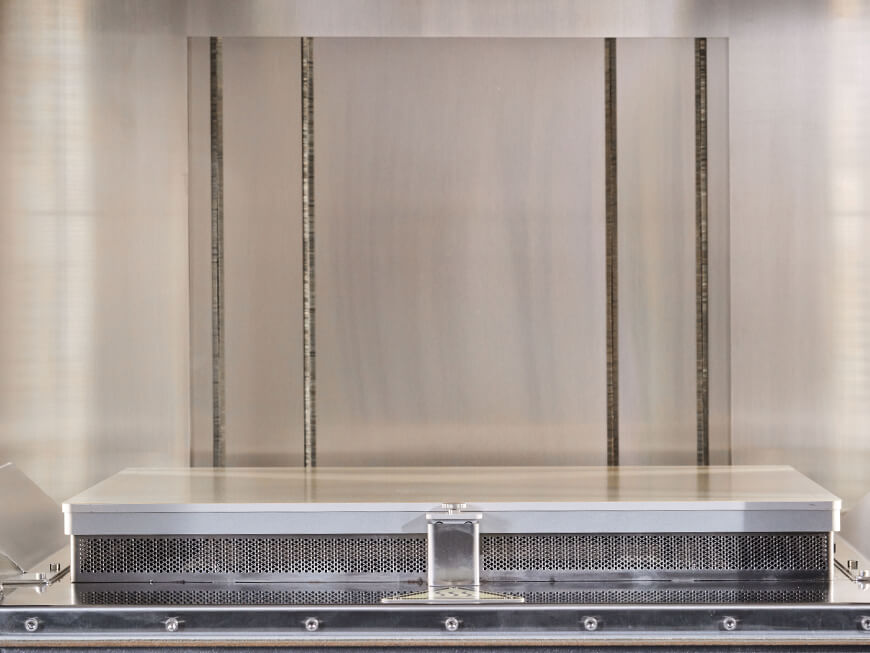

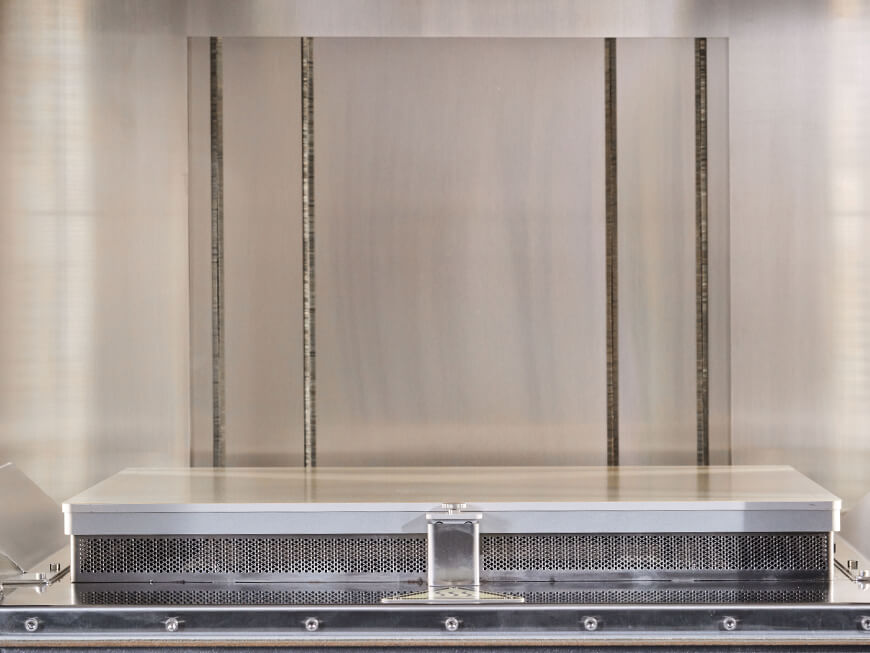

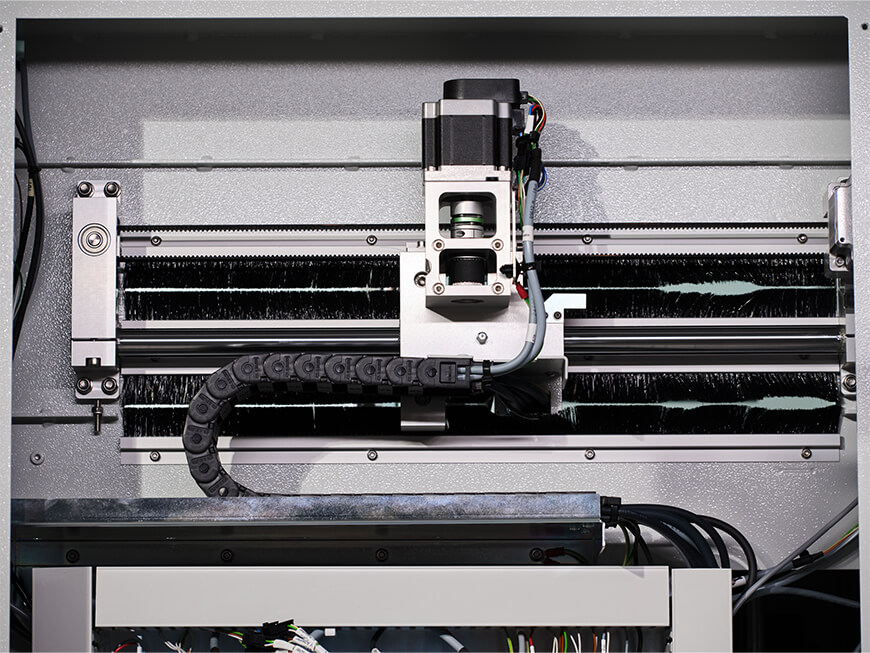

MACHINE CONSTRUCTION QUALITY & PERFORMANCE FOR THE HIGHEST DEMANDS

The quality of materials, components and control of innovatiQ 3D printers is an indispensable benchmark in the entire production process. From development to design, production and assembly, quality control through to installation and commissioning, the high requirements for long-term reliable use in an industrial environment must be guaranteed!

MORE EFFICIENCY AND FASTER AVAILABILITY:

3D PRINTING IN INDUSTRIAL USE.

The innovatiQ FDM printers offer outstanding machine quality, top performance data and a high degree of reliability in industrial use. And all this with comparativelylow maintenance and material costs as well as attractive cost efficiency for e.g.tools, prototypes and small series.

The use of this technology ensures rapid availability and the ability to manufacture components with high load-bearing capacity (e.g. fiber-reinforced plastics) and special requirements (e.g. high-temperature plastics). Designs can be created digitally, adapted immediately andprinted within a few hours. Thissaves an enormous amount of time in product development and the entire production process.

High flexibility in component design, implementation of evencomplex geometries, cavities or integrated functions can be easily realized - often even in a single production step. The use of an innovatiQ 3D printer makes it possible toproduce functional and resilient prototypes and equipment such as assembly aids or devicesdirectly and quickly in-house. This reduces external dependencies andincreases the speed of reaction in production.

In terms ofmaterials, innovatiQ'sopen material system offers the use of almost all plastics available on the market (assuming the necessary machine parameters are suitable), depending on the requirements for stability, temperature or chemical resistance.

FDM printing can be easily integrated into digital and automated processes.Smart functions such as automatic calibration, material monitoring or intelligent insertion functions increase process reliability and make operation easier.

To summarize: The use of innovatiQ 3D printers creates a versatile, economical and fast in-house production technology - ideal for the flexible, efficient and cost-effective production of components in industry. Here are some examples, including production data:

APPLICATION EXAMPLE MECHANICAL ENGINEERING:

EXHAUST AIR FLOW GUIDANCE

TiQ 2 + LiQ 5 | PACF + LSR | 12/3 h |

630 g | 210x180x70 mm | 86,19/37,00 EURO

APPLICATION EXAMPLE AUTOMATION:

EOAT PLATE GRIPPER

TiQ 8 | PACF | 19h |

630 g | 280x300x90 mm | 136,46 EURO

APPLICATION EXAMPLE AUTOMATION:

EOAT INJECTION MOLDING REMOVAL GRIPPER

TiQ 2 | PACF | 14h |

430 g | 220x205x90 mm | 116,46 EURO

SERVICES:

Of course, innovatiQ also offers options such as qualified advice, implementation, on-site set-up by our own service technicians and a wide range of training courses as a service for all of the above devices. In addition, we offer customers for whom the purchase of their own 3D printer is still economical enough, the option of manufacturing their required components as a service .

Even after purchase and installation , you are well looked after: the technicians and specialists in our own service team provide rapid assistance in the event of a problem.