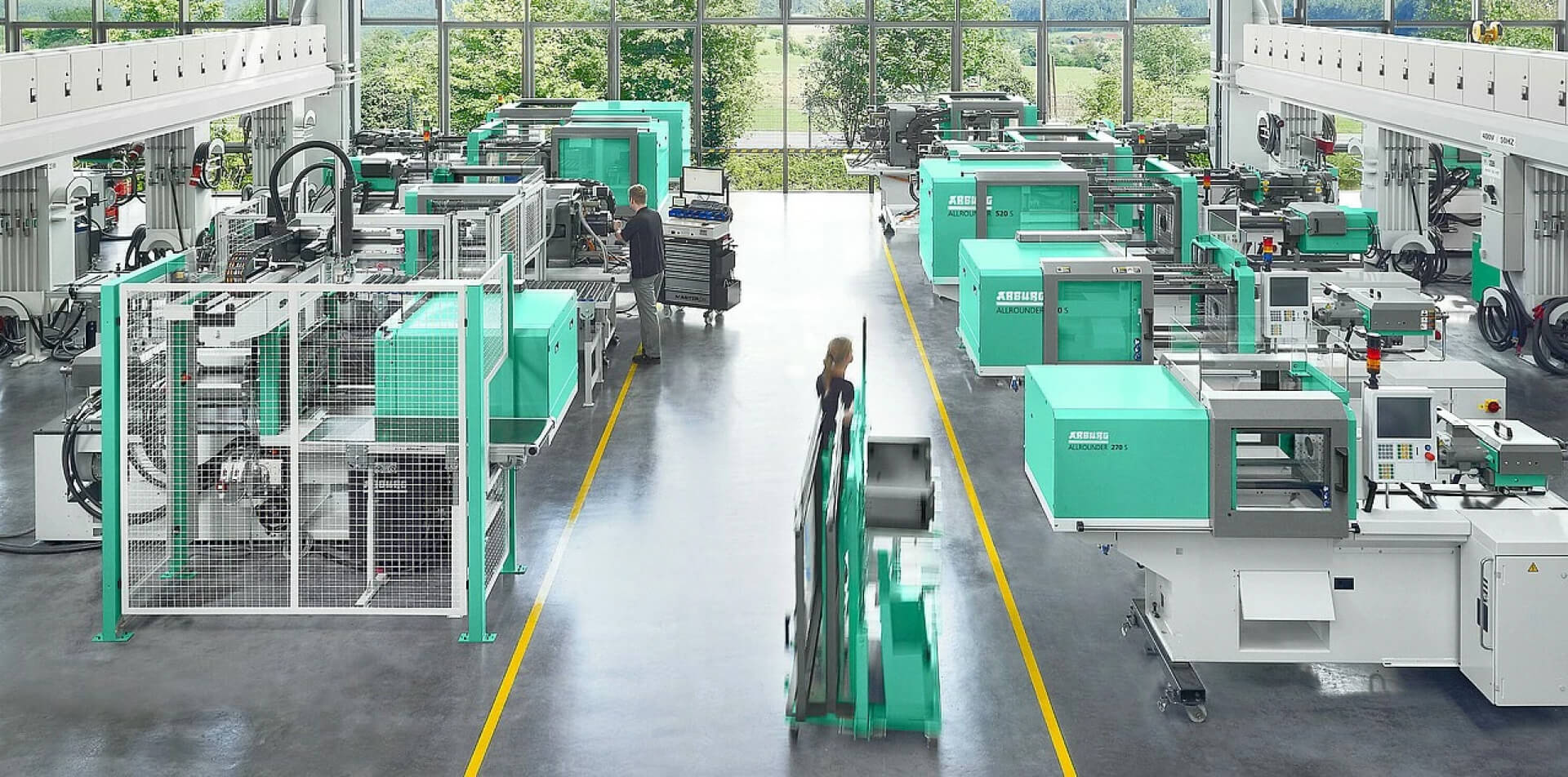

EFFICIENT & RELIABLE QUALITY FOR INDUSTRIAL USE.

3D-printed components are becoming increasingly important in the individual processes of industrial production: thanks to significantly lower production costs and almost just-in-time availability - in contrast to conventional parts production, e.g. by milling at external service providers - production and automation are gaining new momentum.

Examples from our customers' practical experience show how quickly, cost-effectively and resiliently a wide variety of components can be manufactured:

AUTOMATION

BUCKET MILLER

PA CF | 15 h | 169 EURO

MACHINE CONSTRUCTION

EXHAUST AIR DUCTING SYSTEM

PA CF | 11 h | 124 EURO

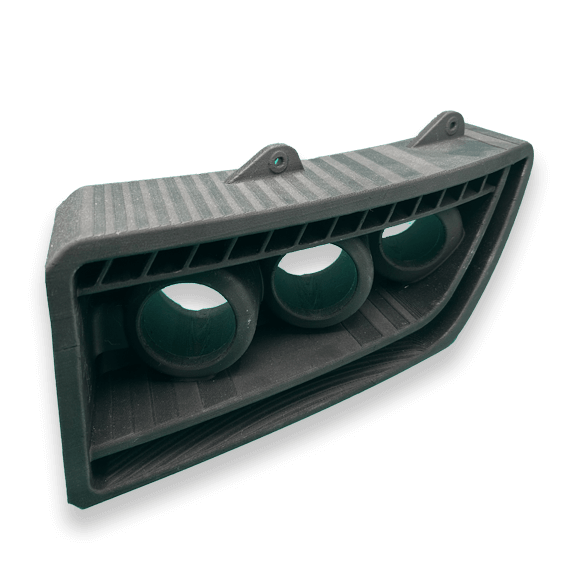

AUTOMOTIVE

CARRIER LIGHTING ELEMENT

PA CF | 13 h | 1146 EURO