HIGH-END 3D PRINTER from innovatiQ!

High-quality mechanical engineering, proven industrial components, high reliability and freedom in material selection provide the ideal configuration for the professional use of innovatiQ 3D printers in industrial environments.

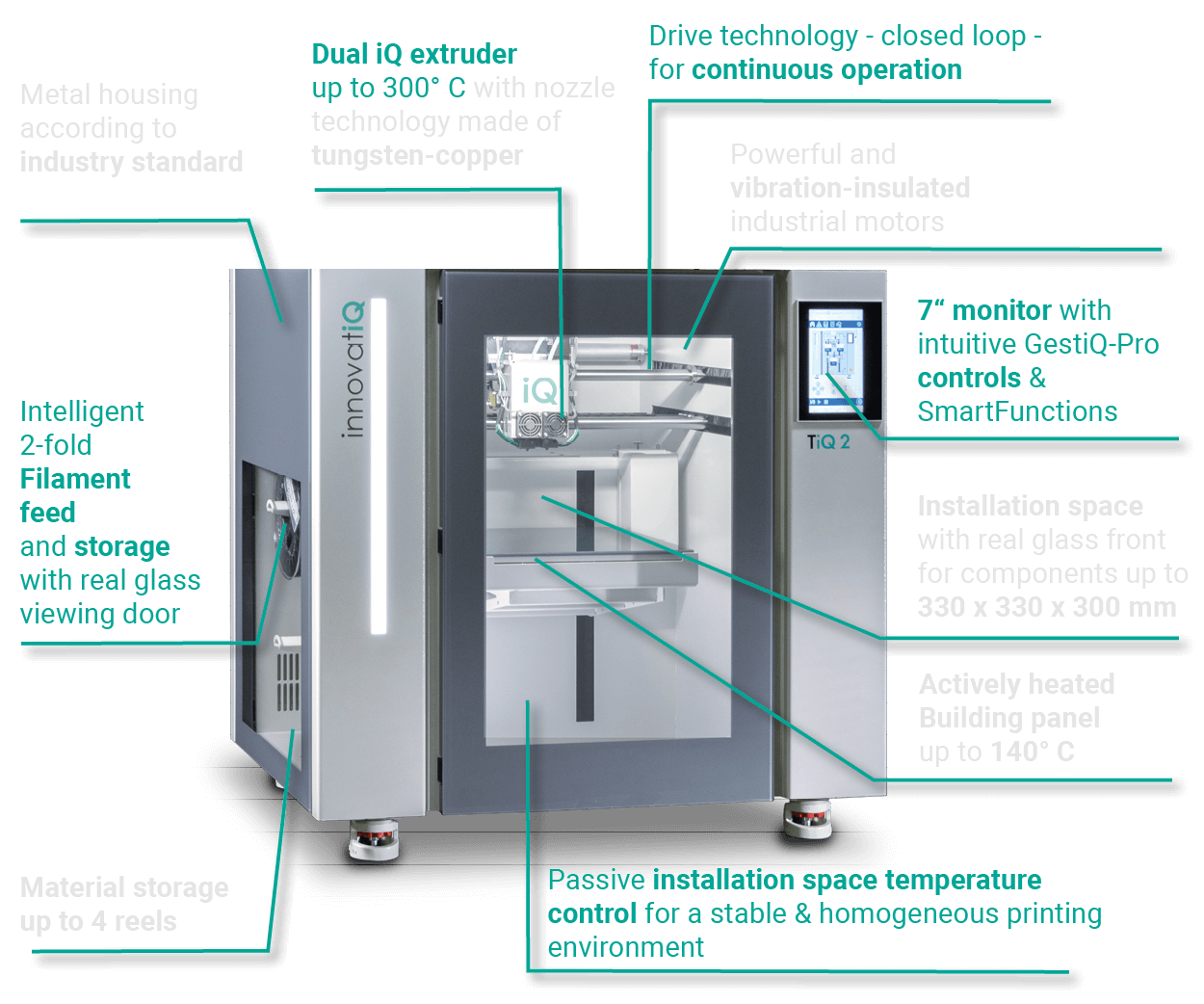

TiQ 2 - THE COMPACT ALL-ROUNDER FOR FFF 3D PRINTING IN INDUSTRIAL USE:

MORE FLEXIBILITY & EFFICIENCY FOR YOUR

PRODUCTION AND MANUFACTURING.

TiQ 2

CONSTRUCTION VOLUME 330 x 330 x 300 MM

DUAL-EXTRUDER/HOTENDS up to 300°C | CONSTRUCTION PLATE140° C

OPEN MATERIAL SYSTEM + iQ-PROFILES FOR RECOMMENDED MATERIALS

OUTER DIMENSIONS: (W/D/H): 900 x 689 x 908 MM | WEIGHT: CA. 165 KG

Recommended materials:

ASA-CF | IGLIDUR | PACF | PAHT-CF | PET | PET CF | PETG-ESD | PLA PRO | PP-GF | TPU | aquatic SUPPORT

Further see: Material

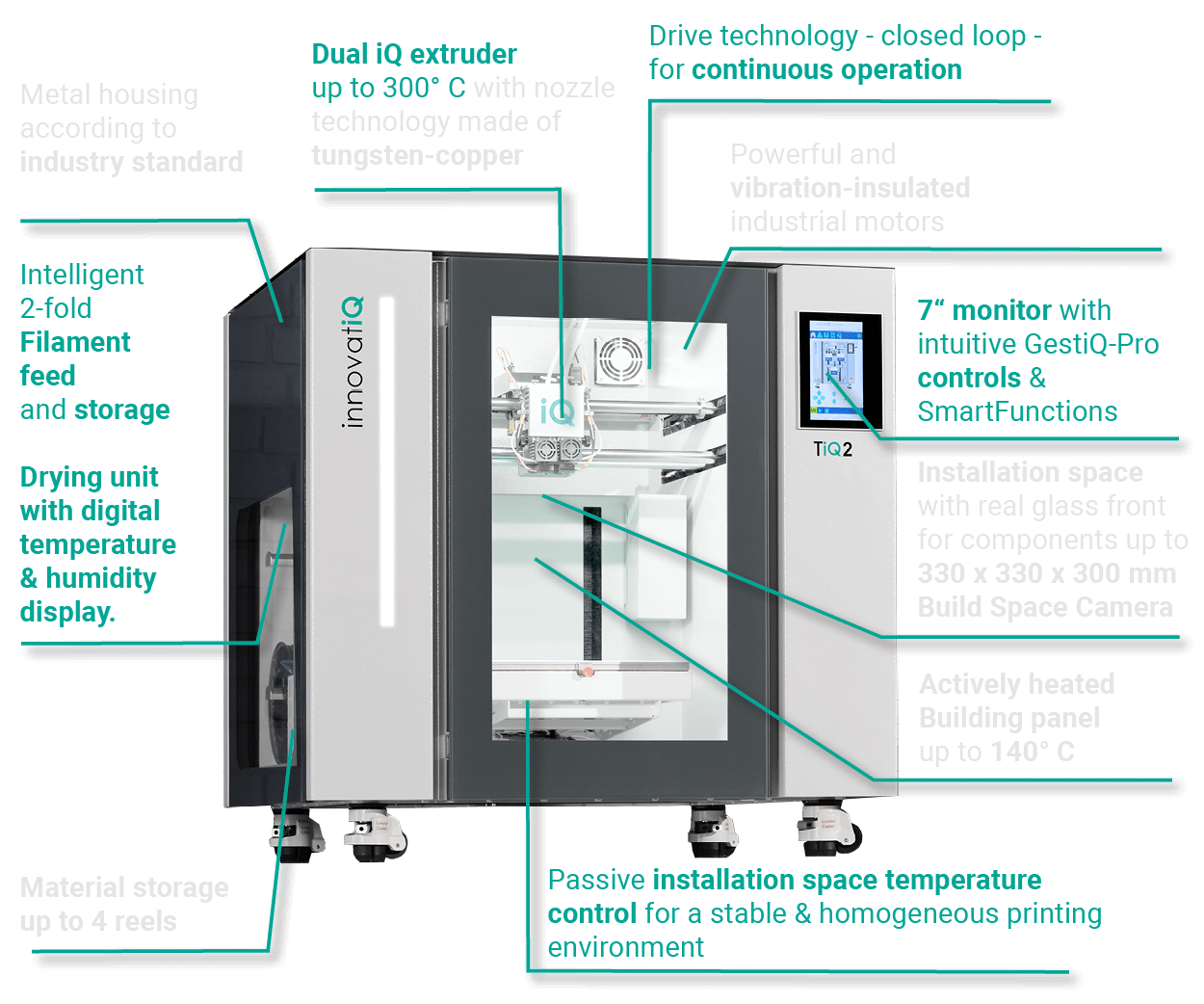

TiQ 2 PLUS - WITH INTEGRATED DRY KEEPING UNIT* AND FURTHER EQUIPMENT OPTIONS.

PROVEN PERFORMANCE NOW WITH UPGRADE OPTION* TO HIGH-TEMPERATURE EXTRUDER FOR PRINTING PPS CF UP TO 340° C

TiQ 2 PLUS

CONSTRUCTION VOLUME 330 x 330 x 300 MM

DUAL EXTRUDER/HOT ENDS UP TO 340°C** | BUILD PLATE 140° C

MATERIAL COMPARTMENT WITH DRY-KEEPING UNIT* AND DIGITAL HUMIDITY AND TEMPERATURE DISPLAY | CONSTRUCTION ROOM CAMERA

OPEN MATERIAL SYSTEM + IQ PROFILES FOR RECOMMENDED MATERIALS

OUTER DIMENSIONS: (W/D/H): 920 x 689 x 908 MM | WEIGHT: CA. 175 KG

Recommended materials:

ASA-CF | IGLIDUR | PACF | PAHT-CF | PET | PET CF | PETG-ESD | PLA PRO | PP-GF | PPS-CF | TPU | aquatic SUPPORT

Further see: Material

* Not available as a retrofit for TiQ 2 basic model

**High-Temp option can be ordered separately as an additional option ex works or as a retrofit kit.

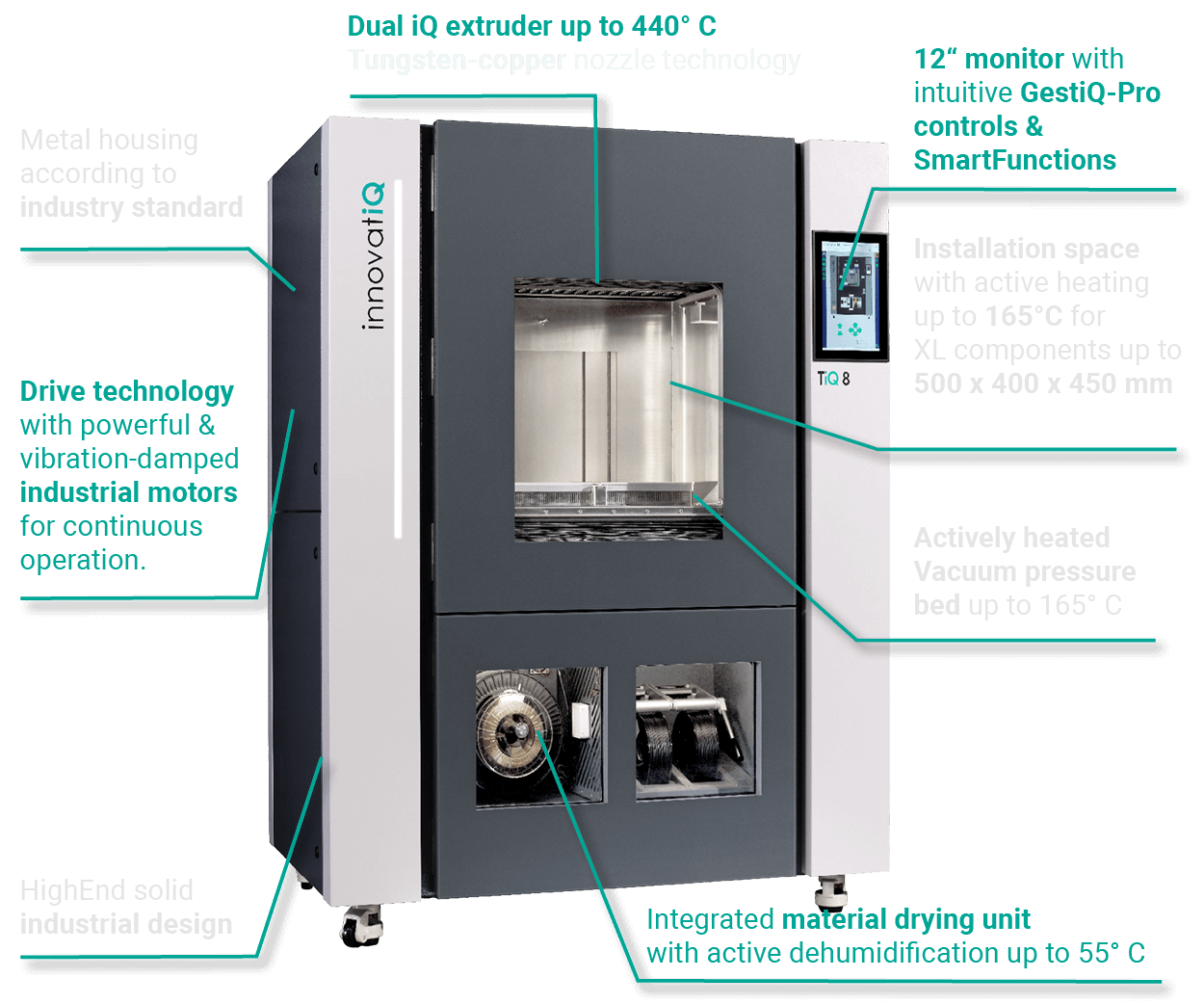

TiQ 8 - THE LARGE-SCALE FDM 3D PRINTER SPECIFICALLY FOR HIGH-TEMPERATURE PRINTING AND DEMANDING APPLICATIONS:

EXCELLENT PRICE/PERFORMANCE RATIO FOR SPECIAL MATERIAL AND APPLICATION REQUIREMENTS.

TiQ 8

CONSTRUCTION VOLUME 500 x 400 x 450 MM

DUAL EXTRUDER/HOTEND 440° C | CONSTRUCTION CHAMBER 165° C | BUILD PLATE 165° C

INTEGRATED ACTIVE DRYING, DEHUMIDIFICATION AND STORAGE AT UP TO55° C

OPEN MATERIAL SYSTEM + iQ PROFILES FOR RECOMMENDED MATERIALS

OUTER DIMENSIONS: (W/D/H): 1480 x 1091 x 1875 MM | WEIGHT: approx. 800 KG

Material compatibility:

ABS | PC | PC/ABS | ESD ABS | PA | PACF | ASA | POLYPRPYLENE | PEKK | PVDF | PPS-CF | IGLIDUR | PEEK CF | aquatiQ SUPPORT | HT Break away SUPPORT

Further see: Material

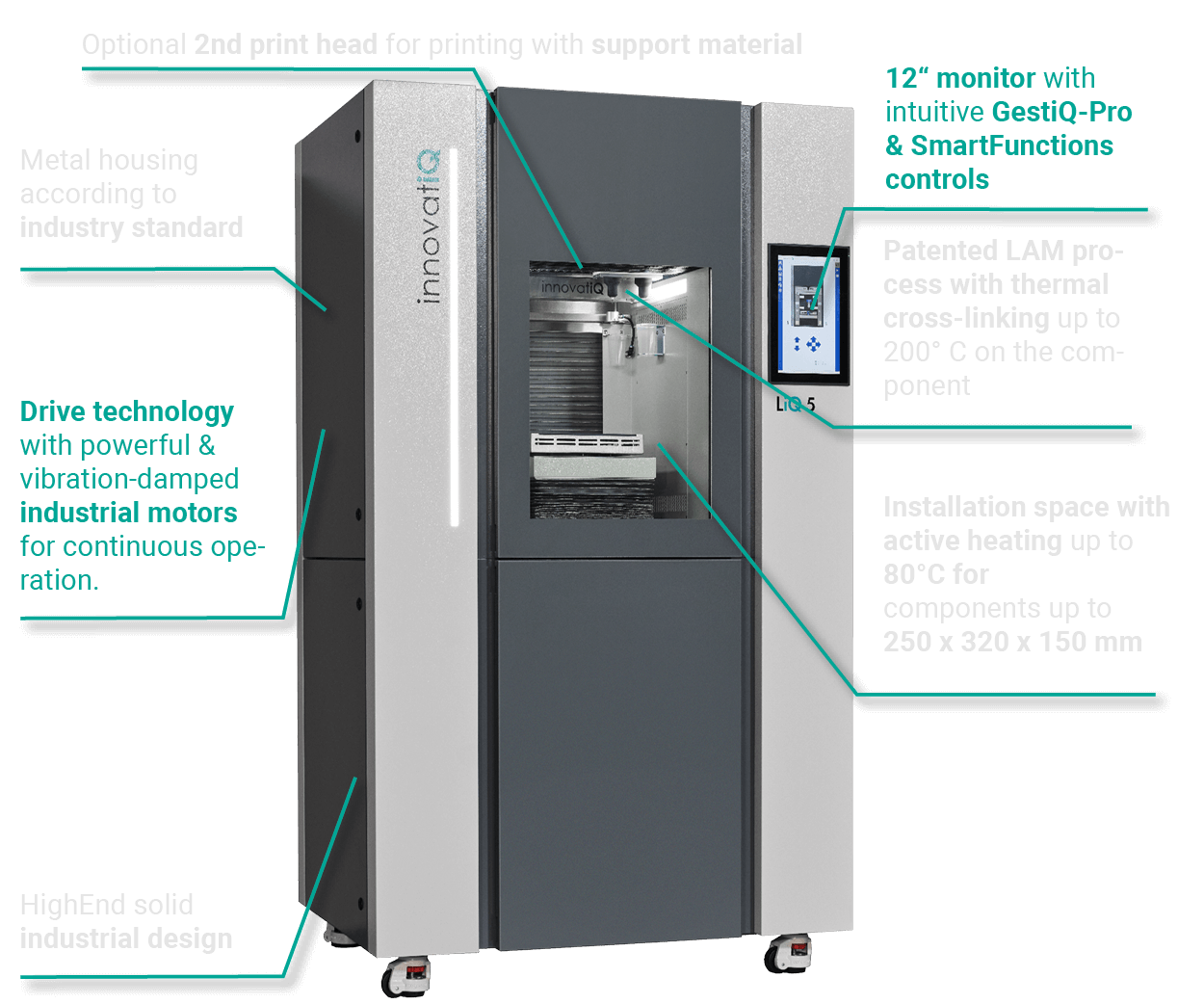

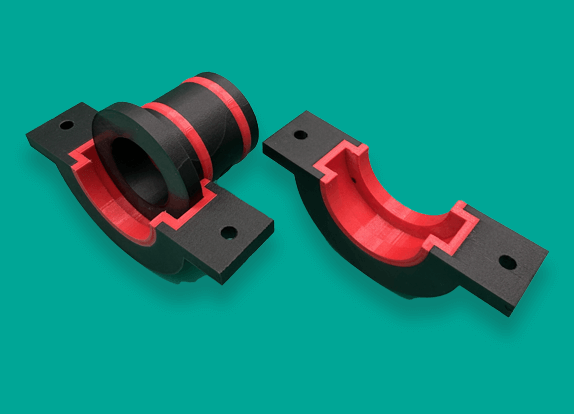

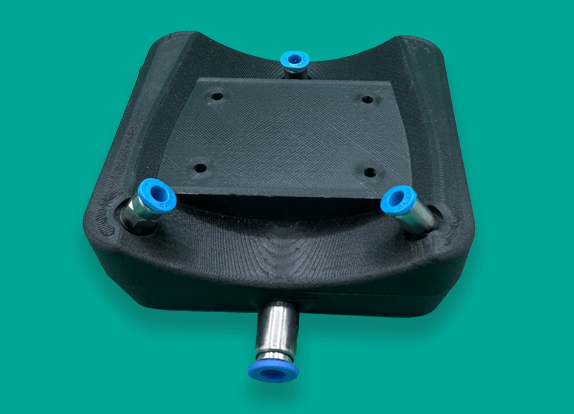

LiQ 5 - LAM 3D PRINTING WITH STANDARD INJECTION MOLDED SILICONE (LSR):

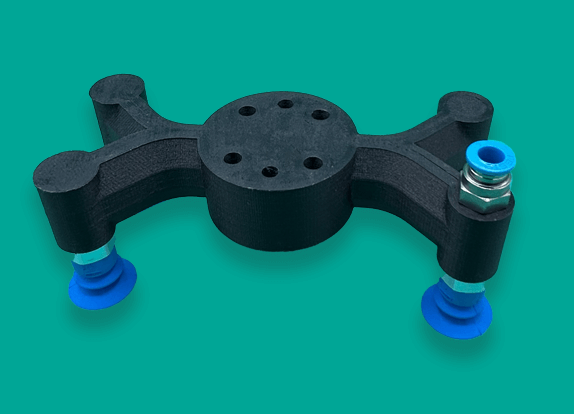

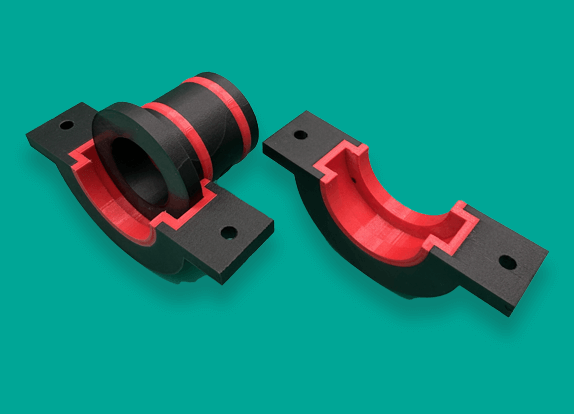

innovatiQ is a pioneer in liquid additive manufacturing. With the LiQ 5, our patented LAM technology with thermal cross-linking of LSR silicone is now in its third generation. The LiQ 5 3D printer is ideal for the additive manufacturing of resilient READY-TO-USE components made from standard LSR silicone. The LiQ 5 has an actively heated build chamber with homogeneous heat distribution for the stable production process of components made from LSR material. The patented innovatiQ LAM manufacturing process makes it possible to produce both prototypes and functional parts with material properties similar to injection molding. The LiQ 5 is considered a trendsetter among silicone 3D printers, particularly due to its high process reliability and a print result without post-processing.

ADDITIVE MANUFACTURING WITH PATENTED THERMAL CROSSLINKING FOR RESILIENT READY-TO-USE SILICONE PARTS.

LiQ 5

CONSTRUCTION SPACE 250 x 320 x 150 MM

BUILD AREA80° C | OPTIONAL 2ND PRINT HEAD FOR SUPPORT MATERIAL

PRINTING WITH LSR SILICONE (SHORE 30 & 50)

thermal bonding up to 200° c on the construction part

OUTER DIMENSIONS: (W/D/H): 1208 x 940 x 1968 mm | WEIGHT: approx. 600 KG

Material recommendation:

LSR silicone: ShinEtsu KEG-2003H 30A | ShinEtsu KEG-2003H 30A

See: Material

MORE INNOVATIQ 3D PRINTERS & DEVICES

(SALE STOCK & REFURBISHED)

Take advantage of access to devices in stock (e.g. from previous series) to realize your 3D printer requirements quickly and cost-effectively. In addition, we offer you the opportunity to access used innovatiQ 3D printer systems - these systems are completely overhauled and always up to date with the latest software version available. All quality checks are included.

PROVEN 3D PRINTERS FROM PREVIOUS SERIES AND REFURBISHED USED DEVICES.

x500 pro | FDM 3D printer

TiQ 5 | FDM 3D printer

MiQ 5 | Base for TiQ 5/TiQ 2 with active dehumidification at 55°)

LiQ 320 | LAM 3D silicone printer

See PDF download below for all currently available devices!

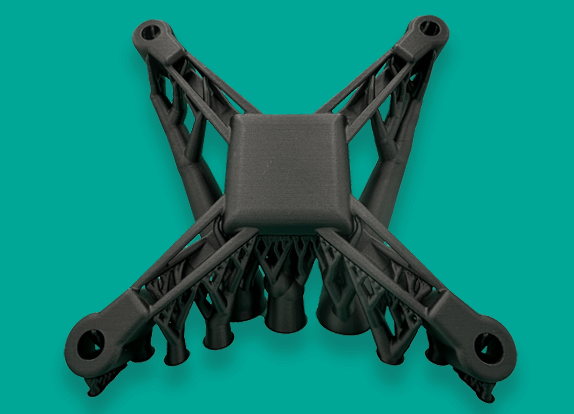

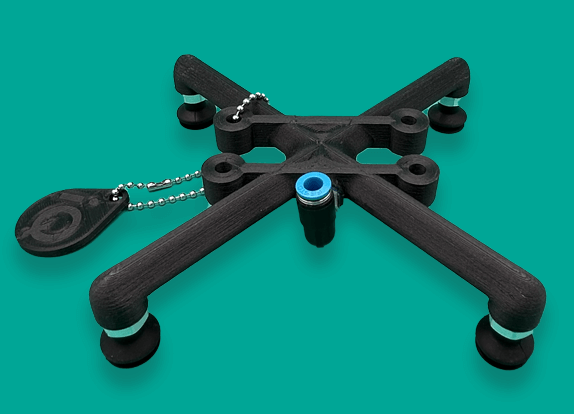

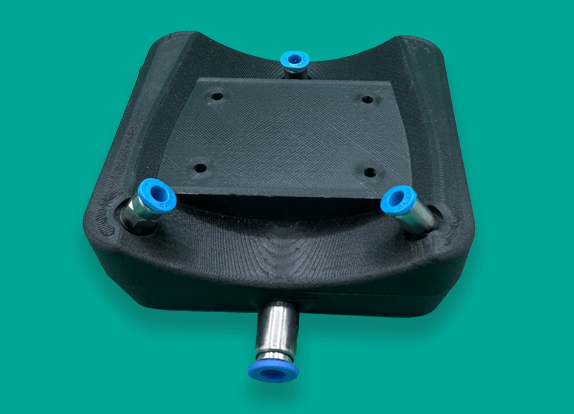

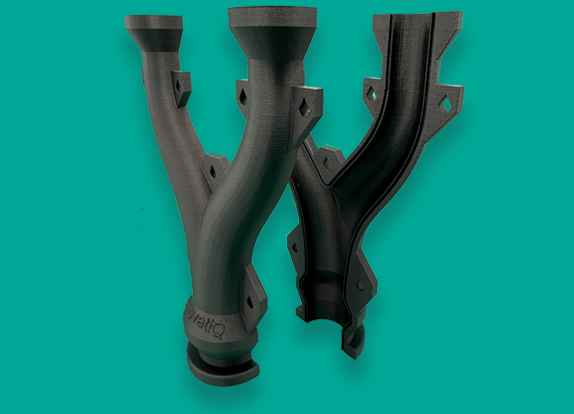

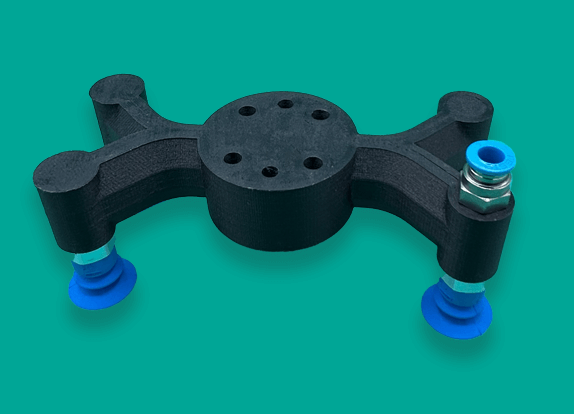

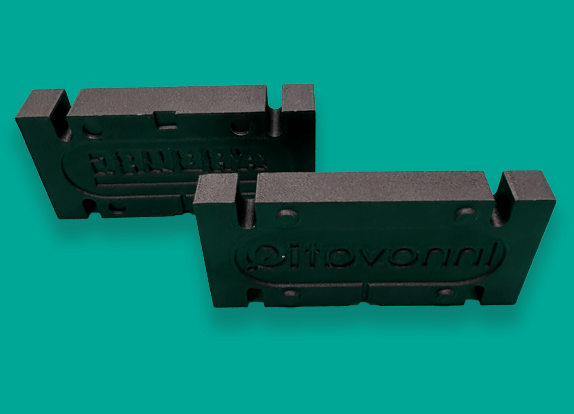

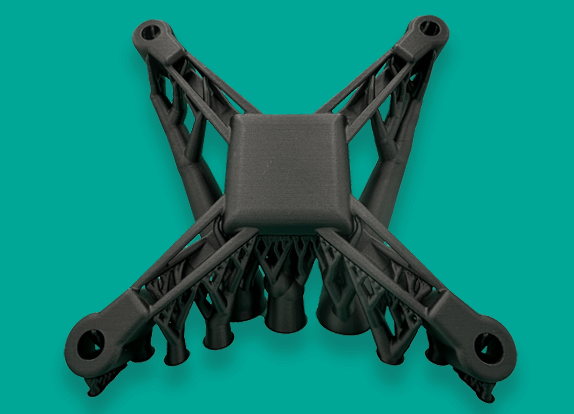

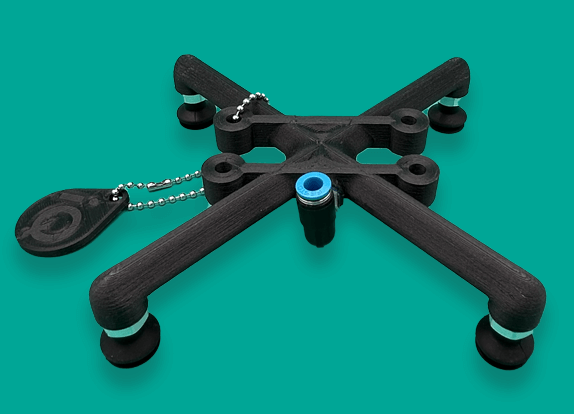

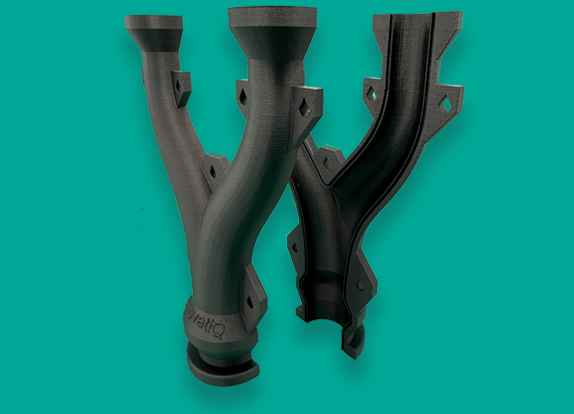

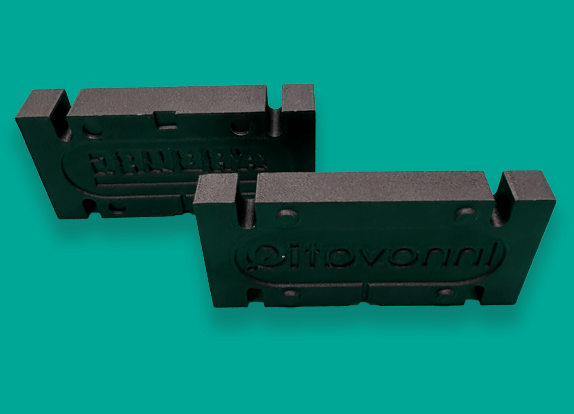

IMPRESSIVE QUALITY & PERFORMANCE:

REQUEST A SAMPLE OR COMPONENT:

We would be happy to create an individual sample part print for you on one of our industrial 3D printing systems. Your individual sample part will be produced according to the 3D data you provide in .STL or .STEP format. Our specialists from our own Application Center will advise you on the choice of printing system and material in the run-up to production.

USER-FRIENDLINESS

THANKS TO SMART FUNCTIONS

SERVICE:

Of course, innovatiQ also offers options such as qualified advice, implementation, on-site set-up by our own service technicians and various training courses as a service for all of the above devices. In addition, we offer customers for whom the purchase of their own 3D printer is still economical enough, the option of manufacturing their required components as a service .

Even after purchase and installation , you are well looked after: the technicians and specialists in our own service team provide rapid assistance in the event of a problem.

Request innovatiQ 3D printer:

You need a written offer for one of the innovatiQ printers - no problem. Please complete this form in full and we will send you a quote with all the details as soon as possible.