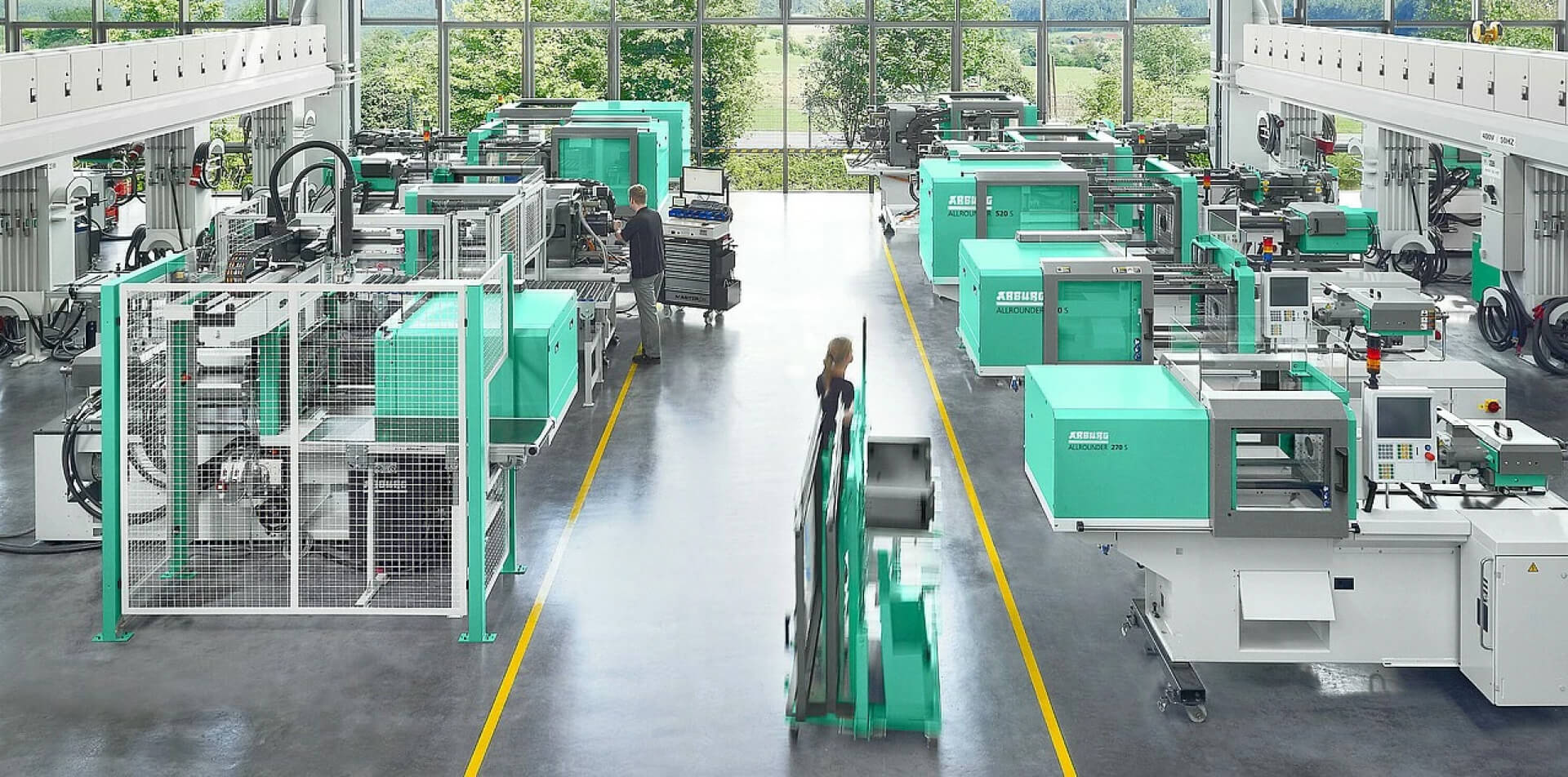

EFFICIENT & RELIABLE QUALITY FOR INDUSTRIAL USE.

3D-printed components are becoming increasingly important in the individual processes of industrial production: thanks to significantly lower production costs and almost just-in-time availability - in contrast to conventional parts production, e.g. by milling at external service providers - production and automation are gaining new momentum.

Practical examples from our customers show how quickly, cost-effectively and resiliently a wide variety of components can be manufactured:

AUTOMATION

EOAT BUCKET GRIPPER

PA CF | 8 h | 79,00 EURO

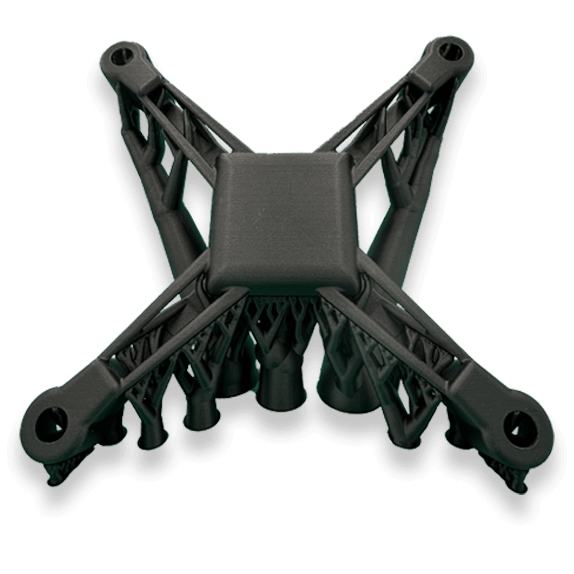

PROTOTYPE CONSTRUCTION

DRONE CARRIERS

PA CF | 13 h | 139,00 EURO

AUTOMATION

EOAT GRIPPER

PPS | 9 h | 85 EURO